Wholesale OEM metal bond- Ceramic white corundum non porous special wheel – Kemei

Wholesale OEM metal bond- Ceramic white corundum non porous special wheel – Kemei

Wholesale OEM metal bond- Ceramic white corundum non porous special wheel – Kemei Detail:

Correct installation of grinding wheel:

1. Before installation, check the grinding wheel carefully for cracks, and knock the grinding wheel with a wooden hammer to see if there is a mute sound. If there is a crack or mute sound, it is strictly prohibited to install and use.

2. Before the installation of the grinding wheel, check whether the maximum linear speed marked on the surface of the grinding wheel matches the spindle speed of the grinding machine. It is strictly prohibited to use the grinding wheel in overspeed.

3. When installing the grinding wheel, the chuck shall be used for fastening. The outer diameter of the two chucks must be the same. Between the two chucks and the end face of the grinding wheel, an asbestos pad, a rubber pad or a paper pad made of elastic material with a thickness of 1-1.5mm shall be placed. And extend more than 1mm outside the circumference of chuck.

4. Before the installation of the grinding wheel, the dirt on the end face of the chuck shall be removed, the gasket shall be checked for completeness, folding, etc., and the dirt and sand particles on the surface near the grinding wheel hole shall be removed.

5. The matching tightness of the grinding wheel aperture and the spindle of the machine tool shall be appropriate. If it is too tight, it is easy to cause the grinding wheel to break, and if the gap is too large, it is easy to cause the imbalance or the grinding wheel to break.

6. When more than one grinding wheel is installed on a spindle, there shall be no fulcrum between the contact surfaces of the grinding wheel; a 0.8-1mm elastic washer is allowed to be padded between the two grinding wheels, and the diameter of the washer shall be the same as that of the chuck.

7. When tightening the grinding wheel, a special hand nut wrench shall be used. It is strictly forbidden to use supplementary clamps or knocking tools. When pressing the screws, they shall be tightened in diagonal sequence with even tightening force. When tightening, pay attention to the degree of tightness of nuts or screws. It is advisable to press it enough to drive the grinding wheel without sliding, so as to prevent the grinding wheel from being damaged due to too much pressing force.

8. The grinding wheel with an outer diameter of 150 mm or more shall be statically balanced after being installed on the chuck, and shall be trimmed after being installed on the grinder. After trimming, the grinding wheel shall be statically balanced again before being used.

Safe use of grinding wheel:

1. Before starting the grinder, check whether the protective device of the machine tool and the reset switch of various actions are adjusted in place and firm.

2. The protective cover used shall cover at least half of the diameter of the grinding wheel.

3. After the grinding wheel is installed on the main shaft of the grinding machine, it must be idle for at least 5 minutes.

4.It is forbidden to use the end face of grinding wheel for grinding if it is not specially used for the end face work.

5.5. During grinding, it is forbidden to use lever to push the workpiece to increase the pressure on the grinding wheel.

6. When grinding or dressing the grinding wheel, the cutting amount should be appropriate. If the cutting amount is too large, the grinding wheel will be broken or the machine tool will be damaged. Special dressing tools shall be used for dressing the grinding wheel.

7. Turn off the coolant before the grinding wheel stops rotating, so as not to affect the balance performance of the grinding wheel.

8. It is forbidden to use grinding fluid that is destructive to abrasive bond.

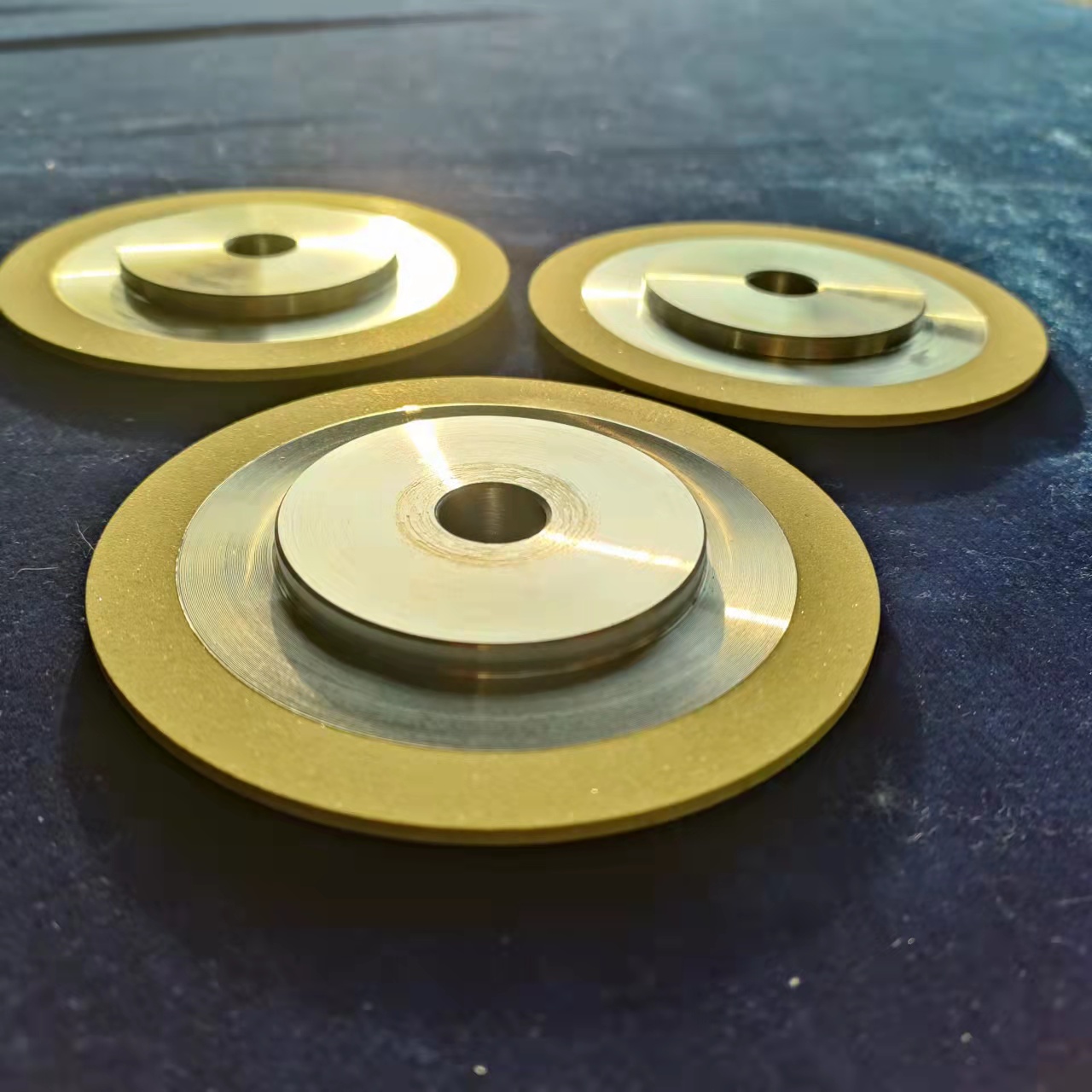

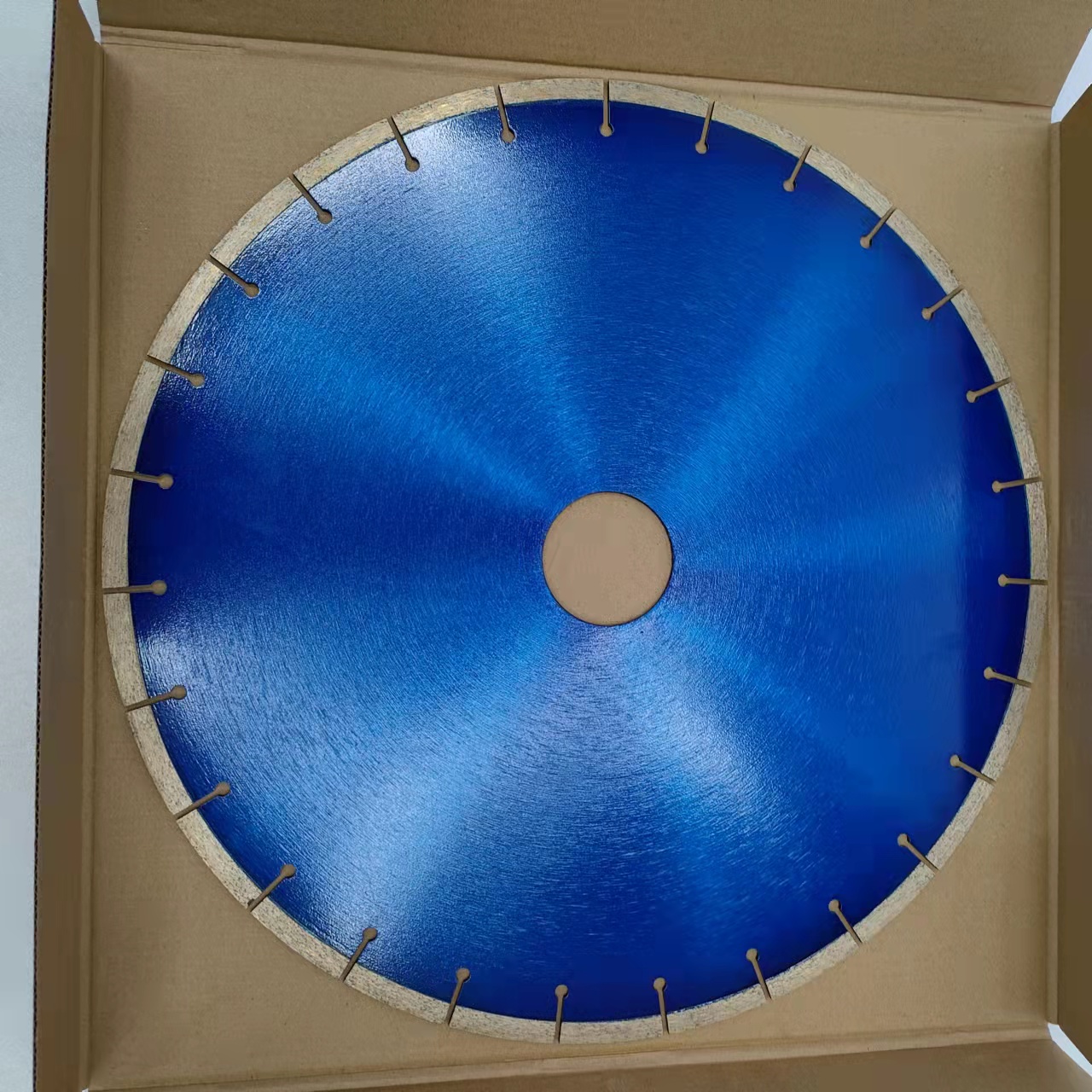

Product detail pictures:

Related Product Guide:

We have a highly efficient team to deal with inquiries from customers. Our goal is "100% customer satisfaction by our product quality, price & our team service" and enjoy a good reputation among clients. With many factories, we can provide a wide range of Wholesale OEM metal bond- Ceramic white corundum non porous special wheel – Kemei , The product will supply to all over the world, such as: Rwanda , Israel , Estonia , We care about every steps of our services, from factory selection, product development & design, price negotiation, inspection, shipping to aftermarket. Now we have implemented a strict and complete quality control system, which ensures that each product can meet quality requirements of customers. Besides, all of our solutions have been strictly inspected before shipment. Your Success, Our Glory: Our aim is to help customers realize their goals. We're making great efforts to achieve this win-win situation and sincerely welcome you to join us.

A good manufacturers, we have cooperated twice, good quality and good service attitude.