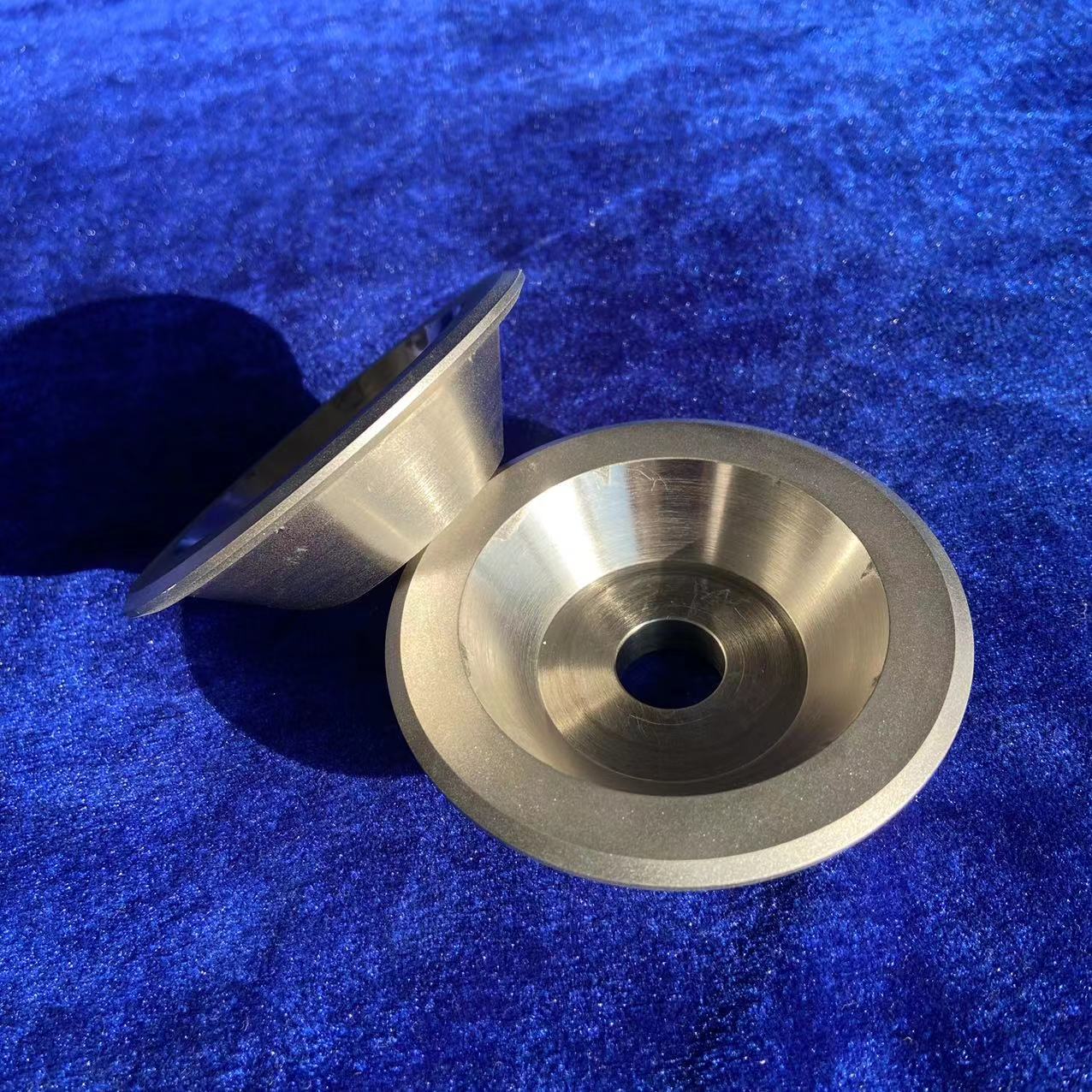

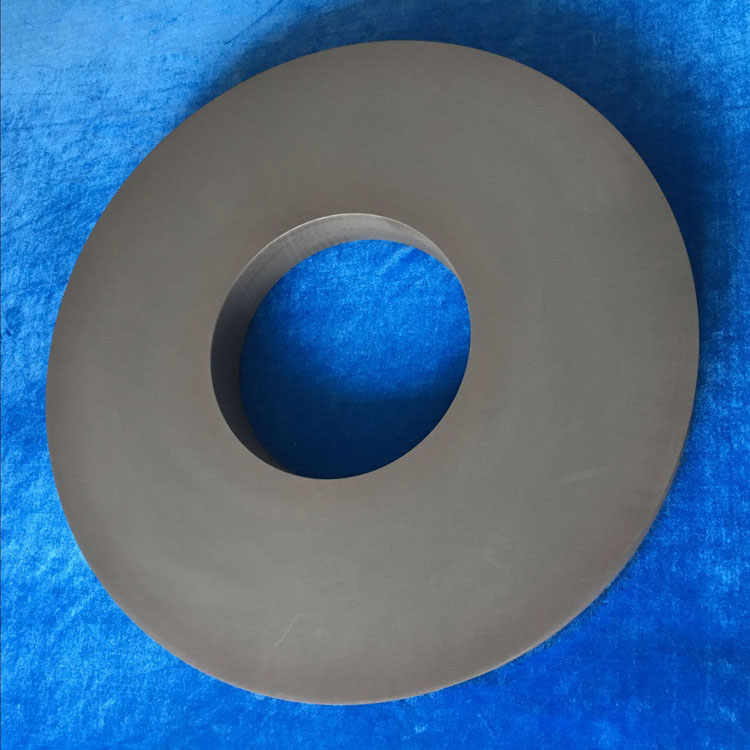

Wholesale OEM cbn grinding wheel 150mm - Resin polishing wheel/Titanium alloy rough grinding wheel/Resin grinding wheel – Kemei

Wholesale OEM cbn grinding wheel 150mm - Resin polishing wheel/Titanium alloy rough grinding wheel/Resin grinding wheel – Kemei

Wholesale OEM cbn grinding wheel 150mm - Resin polishing wheel/Titanium alloy rough grinding wheel/Resin grinding wheel – Kemei Detail:

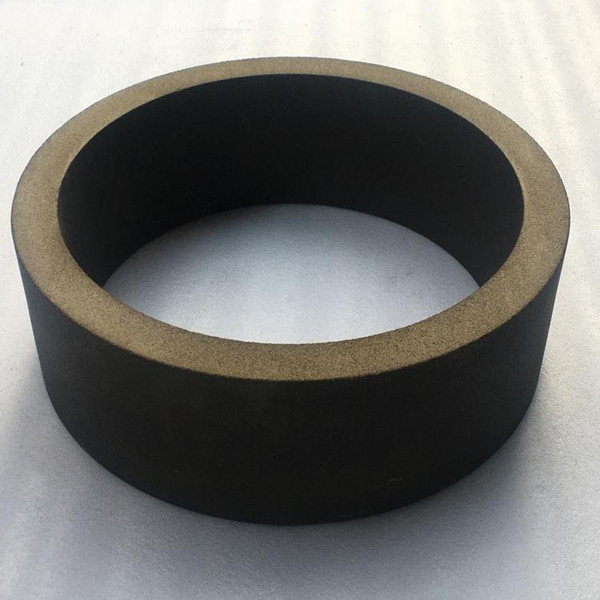

Good retention of the polish is an important factor in determining the polishing capacity and surface finish quality of the polishing wheel, because the polishing is made by adhering to the polishing.

The polishing material on the wheel. This retention is related to the water quality of the polishing wheel material and its affinity with the binder.

Suitable for the above requirements of the polishing wheel material, coarse throwing often used canvas, felt, hard shell paper, cork, leather or hemp.

Then the application of good softness and polishes also good retention of cotton cloth, fine felt and other materials. Liquid in polishing wheel is used with degreased wood or fine felt.

Different polishing materials also need to be bleached, sizing, wax treatment, resin treatment and pharmaceutical treatment and other different treatment methods, in order to increase the softness of the material, improve the ability to maintain the polish, strengthen the fiber, increase the rigidity. And some processing, its purpose is to increase the flammability and lubricity of materials.

The “rigidity” and “elasticity” of the polishing wheel can also be adjusted by the way it is sewn and by the stitching pattern and spacing

It has been strengthened, and is easy to manufacture and use.

Economical and practical, widely used.

Our company, as the leader of precision and ultra precision grinding tools, combines foreign honing technology, advanced technology and high-end equipment in Europe and America, and cooperates with domestic well-known grinding tool research and development institutions. Its high-precision diamond reamer and diamond roller are widely used in the fields of automobile, hydraulic pressure, bearing, machine tool, aerospace and military industry.

Product detail pictures:

Related Product Guide:

Our products are greatly recognized and trustworthy by users and will fulfill continually shifting economic and social requires for Wholesale OEM cbn grinding wheel 150mm - Resin polishing wheel/Titanium alloy rough grinding wheel/Resin grinding wheel – Kemei , The product will supply to all over the world, such as: Cape Town , Hamburg , Paris , Based on our automatic production line, steady material purchase channel and quick subcontract systems have been built in mainland China to meet customer's wider and higher requirement in recent years. We have been looking forward to cooperating with more clients worldwide for common development and mutual benefit!Your trust and approval are the best reward for our efforts. Keeping honest, innovative and efficient, we sincerely expect that we can be business partners to create our brilliant future!

The company has a good reputation in this industry, and finally it tured out that choose them is a good choice.