Supply ODM cutting off wheel- PVA wheel resin rough grinding and fine grinding mirror polishing wheel sponge polishing wheel – Kemei

Supply ODM cutting off wheel- PVA wheel resin rough grinding and fine grinding mirror polishing wheel sponge polishing wheel – Kemei

Supply ODM cutting off wheel- PVA wheel resin rough grinding and fine grinding mirror polishing wheel sponge polishing wheel – Kemei Detail:

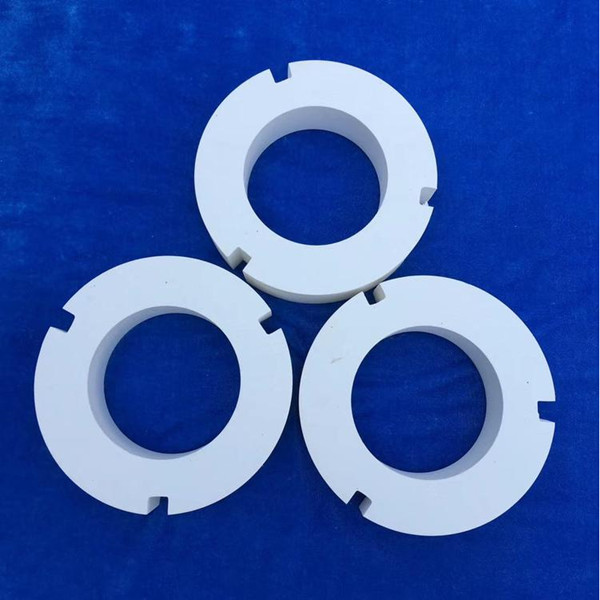

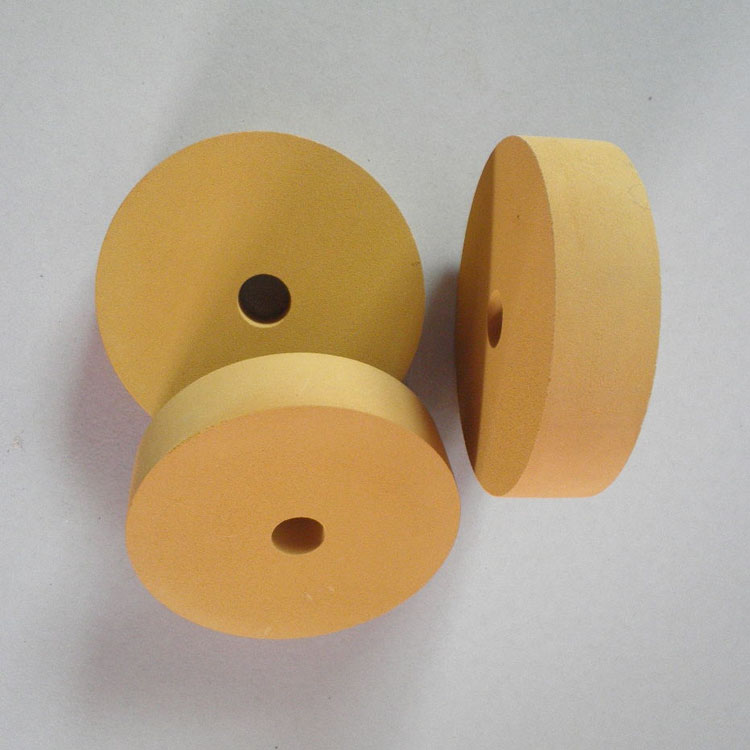

PVA grinding wheel is a kind of elastic grinding wheel combined with polyvinyl alcohol, and its special structure is spongy. PVA grinding wheel has been proved to be a good elastic grinding wheel in the polishing and grinding process because it can greatly save operation cost and improve product quality through automation. 1. With PVA as the remarkable material, such elastic effect can make the cutting depth caused by abrasive consistent, and achieve excellent fine surface and flatness through this, and also can avoid too deep scratches on the surface. 2. The unique and regular pores allow long-lasting grinding, and reduce the generation of grinding heat due to less blockage. 3. PVA has good consistency for curved surface, so compared with other abrasives such as sandpaper or iron polishing wheel, PVA grinding wheel can grind excellent fine surface.

Features of PVA grinding wheel: PVA sponge polishing wheel adopts special synthetic resin to strengthen its wear resistance and grinding force. By the presence of special air holes, the grinding debris can be quickly removed without filling and heating, so as to avoid heating and burning the workpiece. It is suitable for long-time grinding. The binder is soft and buffering, and there is no deep defect on the grinding surface.

PVA grinding wheel uses: 1. Use of general grinding wheel and emery cloth is easy to produce heating and filling material phenomenon. It is used to grind stainless steel, aluminum, copper, iron, wood, gem, marble, glass, graphite products, electric University urea products and leather, etc. PVA sponge wheel is the most suitable. In addition, it can eliminate burr, dirt, rust, etc.

2. Using PVA sponge grinding wheel, we can get beautiful grinding surface and omit engineering number after a short working time. For example, grinding of various metals, copper mixing cylinder (centerless polishing), case, strap, gem, marble before electroplating or polishing.

Product detail pictures:

Related Product Guide:

In the past few years, our business absorbed and digested advanced technologies both equally at home and abroad. In the meantime, our company staffs a group of experts devoted to your advancement of Supply ODM cutting off wheel- PVA wheel resin rough grinding and fine grinding mirror polishing wheel sponge polishing wheel – Kemei , The product will supply to all over the world, such as: Puerto Rico , Austria , Estonia , Our solutions have national accreditation standards for experienced, premium quality items, affordable value, was welcomed by people around the globe. Our goods will continue to increase in the order and look forward to cooperation with you, Really should any of those products be of interest to you, please letus know. We are going to be pleased to give you a quotation up on receipt of one's detailed specifications.

In China, we have purchased many times, this time is the most successful and most satisfactory, a sincere and realiable Chinese manufacturer!