Renewable Design for vitrified bond- Resin diamond CBN bowl wheel – Kemei

Renewable Design for vitrified bond- Resin diamond CBN bowl wheel – Kemei

Renewable Design for vitrified bond- Resin diamond CBN bowl wheel – Kemei Detail:

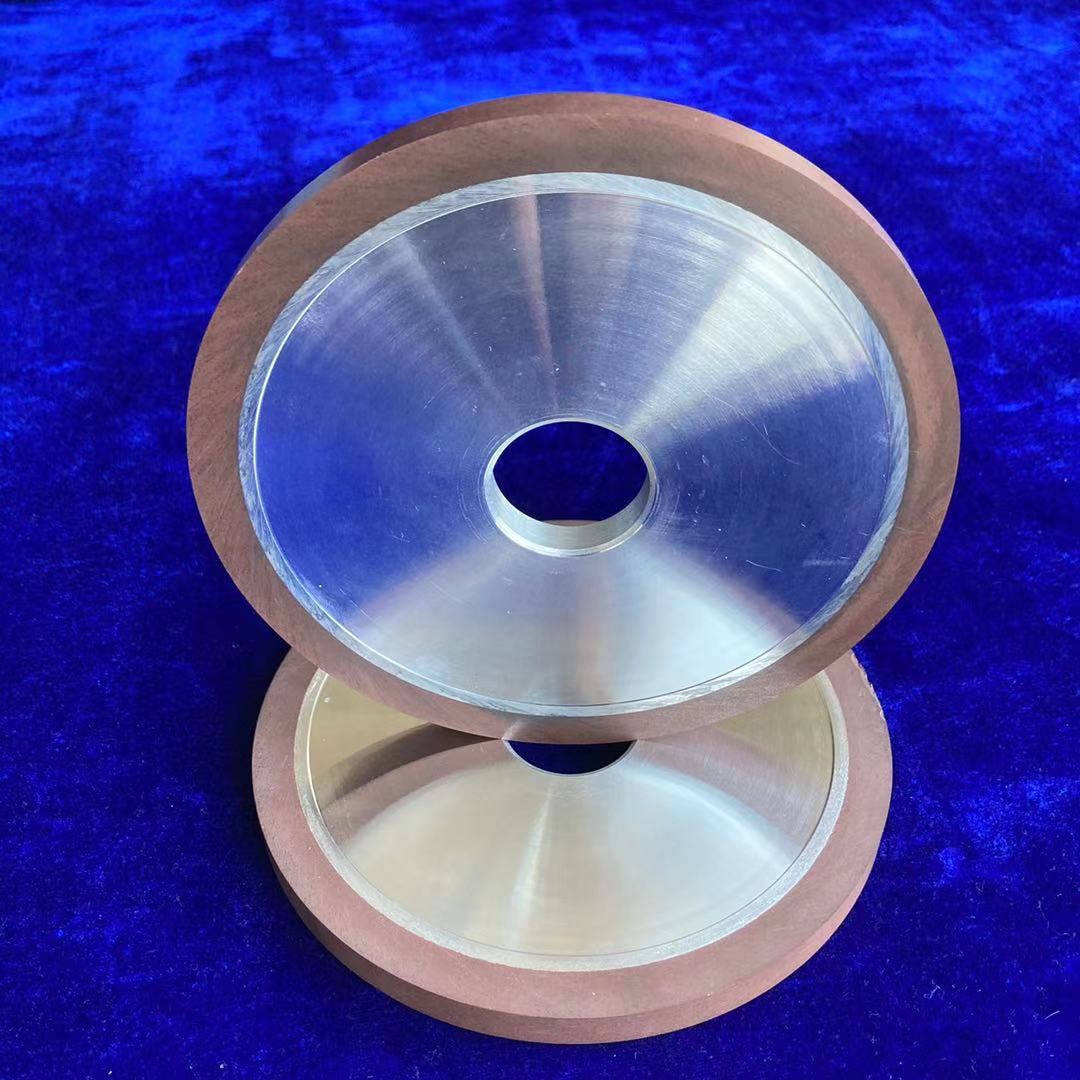

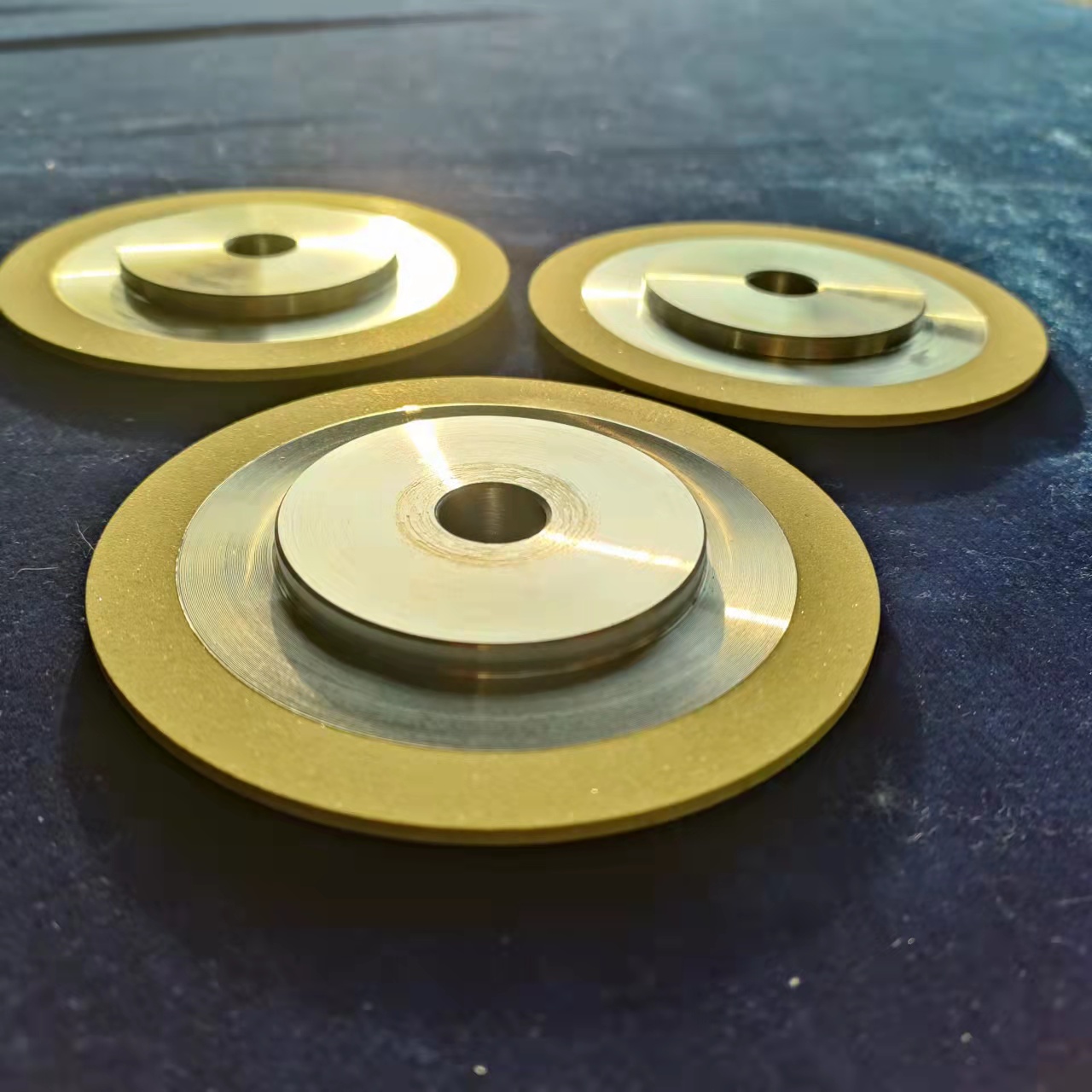

Resin bonded 11 v9 4 inch bowl shape diamond CBN grinding wheel for stainless steel grinding

|

Name |

11v9 resin diamond grinding wheel |

|

|

Bond |

Resin bond |

|

|

Abrasive |

Diamond and CBN |

|

|

Size |

D:25mm-500mm T: 5mm-40mm H:10mm-127mm |

|

|

Type code |

1A1, 1V1, 1EE1, 1FF1, 3A1, 11A2, 6A9, 14A1,14A1R,11V9, 11C9, 4A2, 6A1,6A2, 12A2, 9A3, 1F1,12V2, 1L1, 14EE1, 4B1, 14E1, 4A2P, 11B2, 6A2T, 11V2, 9A1, 1A1R, 1F1, 1A8, 9A1, 9A1B,3K1, 1A1W, 4V2, 1A3, 1A2T,1A2, 12C9 14E6Q, etc. |

|

|

Usage |

Mainly used for grinding , sharping and polsihing . Widly used in the filed of PCD, CVD, PCBN ceramic, diamond processing, sapphire processing, stone , glass, ceramic, bearing, compressor , car engine processing industry, precision machining,etc |

|

|

Scope of application |

|

|

|

characteristics |

Sharp grinding, high processing efficiency The cutting edge of surface machining machine is of good quality High durability, long service life |

Resin diamond and CBN grinding wheel are super hard tools made of resin, diamond, or CBN, and other materials

Mainly used in: various alloys, high speed steel, hard alloy, glass, crystal, cutting and grinding processing.

Selection of grinding wheel elements.

(1) hard grinding material, choose the soft, fine grit grinding wheel. Soft grinding material, should choose a hard, coarse grit grinding wheel. By doing this ,grinding wheel loss is small, also not easy to plug.

(2) when doing the rough grinding ,in order to increase the productivity, the coarse grit, soft grinding wheel should be chosen, In order to improve the surface quality of the work piece during accurate grinding , the fine grit ,hard grinding wheel should be chosen.

(3) the large area of grinding or thin-walled work piece grinding should choose the coarse grit, soft grinding wheel. This wheel is not easy to plug, the surface of the work piece is not easy to burn, the work piece is not easy to deformation.

(4) form grinding process to select the fine grit, the small organization, and the hard grinding wheel to maintain the profile of the grinding wheel.

Product detail pictures:

Related Product Guide:

We constantly believe that one's character decides products' high quality, the details decides products' high-quality ,together with the REALISTIC,EFFICIENT AND INNOVATIVE crew spirit for Renewable Design for vitrified bond- Resin diamond CBN bowl wheel – Kemei , The product will supply to all over the world, such as: Hyderabad , Kyrgyzstan , kazan , If you give us a list of merchandise you are interested in, along with makes and models, we can send you quotations. Remember to email us directly. Our goal is to establish long-term and mutually profitable business relationships with domestic and overseas clients. We look forward to receiving your reply soon.

We are old friends, the company's product quality has been always very good and this time the price is also very cheap.