Renewable Design for 180mm diamond disc - Sanding Belts Grinding Plate – Kemei

Renewable Design for 180mm diamond disc - Sanding Belts Grinding Plate – Kemei

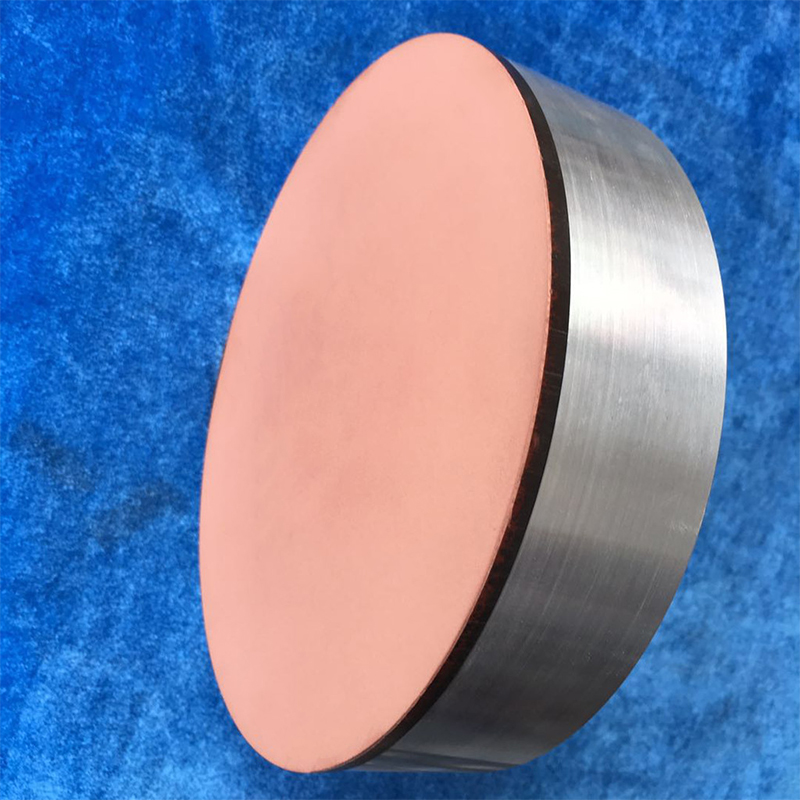

Renewable Design for 180mm diamond disc - Sanding Belts Grinding Plate – Kemei Detail:

About the product:

This customized diamond plate is used for sanding belt polishing.

Metal bond products are made of metal or alloy powder as the bonding material through the process of preparation, mixing, hot or cold pressing, and sintering.

Features: High bonding strength, good formability, high temperature resistance, good thermal conductivity and abrasion resistance, long service life, and can withstand larger loads.

Application:precision ceramics, gem glass, magnetic material cemented carbide, stone and others.

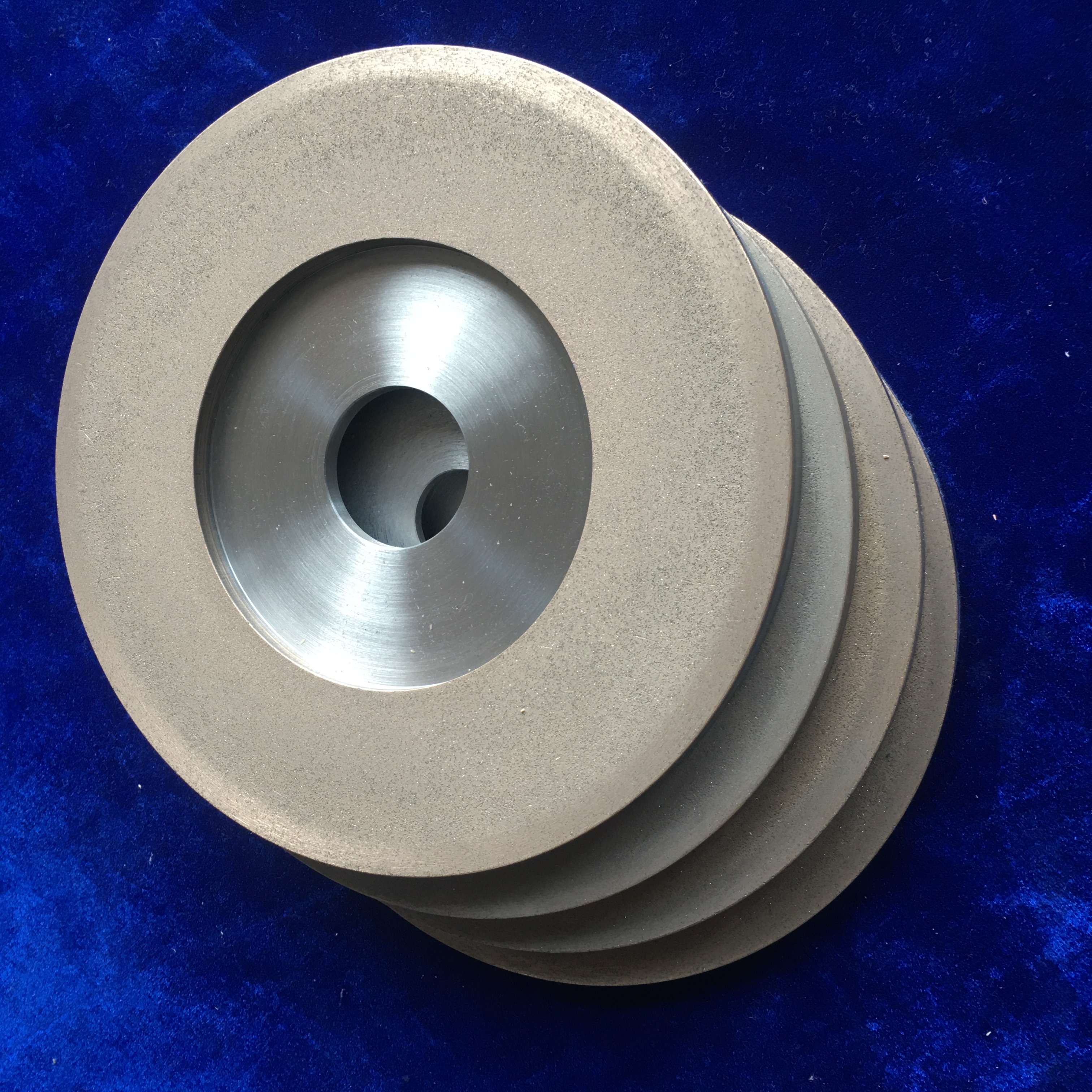

A diamond wheel is a super hard abrasive wheel. Compared with an ordinary abrasive wheel, the diamond wheel has very obvious characteristics and advantages:

1.The hardness of a diamond abrasive determines the main characteristics of a diamond grinding wheel, which can grind hard alloy, glass, ceramics, and other difficult materials efficiently, and the grinding tool has a long service life.

2.In grinding, the size, shape, and morphology of diamond grains change little, which is more suitable for high-precision machining and has high production efficiency. The diamond grinding wheel can meet the requirements of high-efficiency and precision machining at the same time.

3.The sharpened diamond grinding wheel can maintain the micro-edge property of the grinding grains for a long time, and the good cutting performance ensures less grinding force in the grinding process, thus reducing the grinding power and saving energy.

4.The sharpened diamond grinding wheel can maintain the micro-edge property of the grinding grains for a long time, and the good cutting performance ensures less grinding force in the grinding process, thus reducing the grinding power and saving energy.

The bronze sintered diamond cutting disc is applied to cut the glass, hard alloy, magnet, ceramics, tungsten steel, jade, crystal, agate, etc.

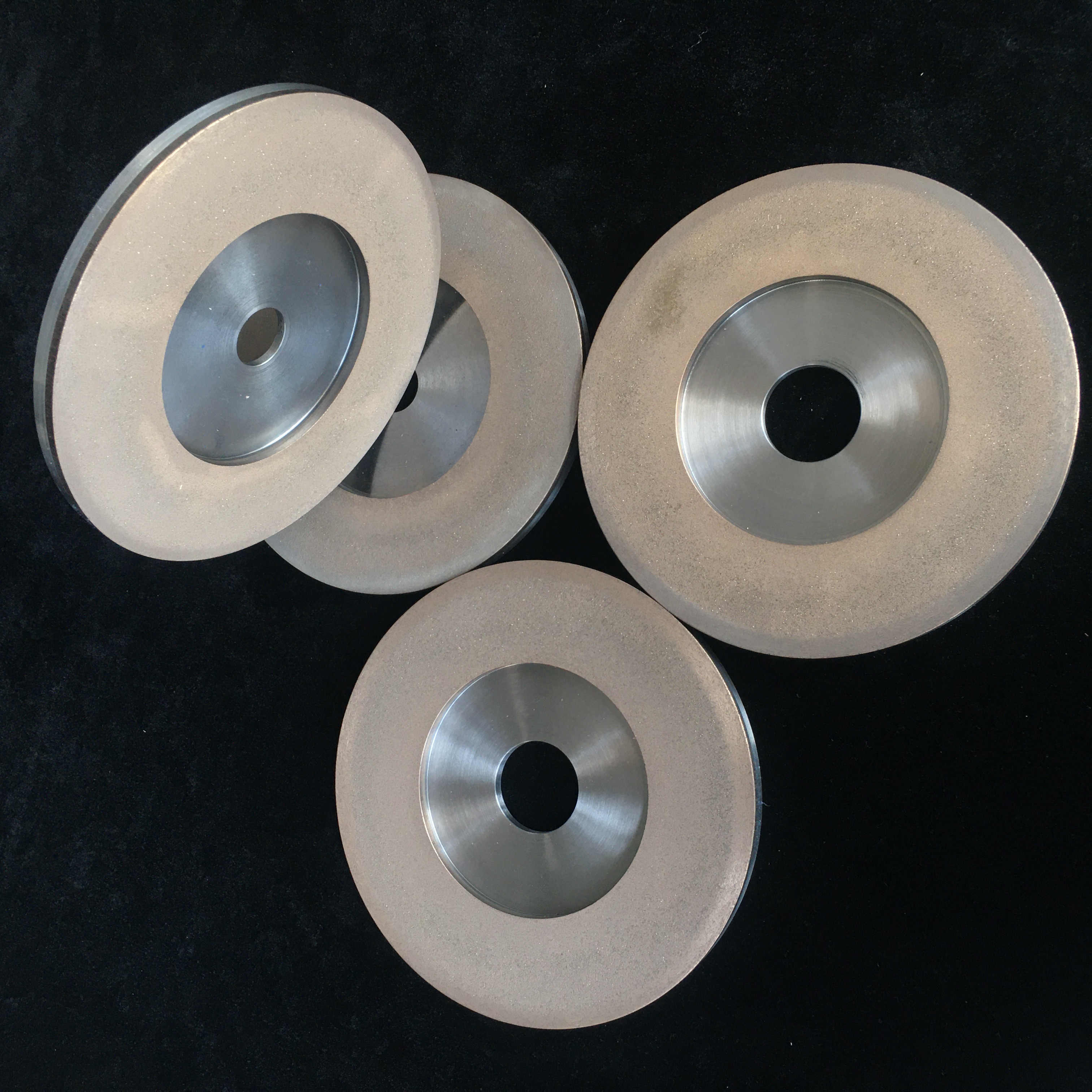

Specialties & Customed Production

As the leader of precision and ultra-precision grinding tools, we can offer you bronze bonded diamond wheels with high quality, high performance, and longer cycle time.

we can make the only grinding wheel for you, based on your applications and special requirement.

If you have special needs on the product, leave us the following information:

|

shape |

size |

working layer width |

|

bond/binding agent/adhesive |

Abrasive grain |

grit designation |

|

diamond concentration |

dry /wet grinding |

And tell us the product or material you want to work on or your applications, then we can provide you the professional suggestions.

What you may concern:

1: Are you a factory?

Yes, we are the producer. Our main products are diamond tools, grinding wheels, cut-off discs, sanding belts, oil stones, mounted points, etc.

2, Can I get free samples?

Yes, within 20USD samples, we can provide for free, but the shipping cost should be covered by the customers.

3, How to confirm the quality?

We have the most experienced technicians and producers. You can send us the technical parameters of the product and we will produce according to your requirements. You can ask for a sample for free. You can have a pilot order before normal order.

4, What about quality control?

We are using the highest quality components & an efficient manufacturing process. We have the strictest QC process. We are proving a high level of service for customers and distributors. We are trying to nail down the quality complaint to zero. We will make you an enjoyable experience working with us.

As the leader of precision and ultra-precision grinding tools, we can offer you bronze bonded diamond wheels with high quality, high performance, and longer cycle time.

we can make the only grinding wheel for you, based on your applications and special requirement.

If you have special needs on the product, leave us the following information:

Product detail pictures:

Related Product Guide:

We also supply merchandise sourcing and flight consolidation companies. We now have our very own manufacturing facility and sourcing business. We could present you with almost every kind of product relevant to our solution array for Renewable Design for 180mm diamond disc - Sanding Belts Grinding Plate – Kemei , The product will supply to all over the world, such as: Russia , Manila , Salt Lake City , Based on our guiding principle of quality is the key to development, we continually strive to exceed our customers' expectations. As such, we sincerely invite all interested companies to contact us for future cooperation, We welcome old and new customers to hold hands together for exploring and developing; For more information, please feel free to contact us. Thanks. Advanced equipment, strict quality control, customer-orientation service, initiative summary and improvement of defects and extensive industry experience enable us to guarantee more customer satisfaction and reputation which, in return, brings us more orders and benefits. If you are interested in any of our products, please feel free to contact us. Inquiry or visit to our company are warmly welcome. We sincerely hope to start a win-win and friendly partnership with you. You can see more details in our website.

The sales person is professional and responsible, warm and polite, we had a pleasant conversation and no language barriers on communication.