Quality Inspection for pore- Special shaped brazed diamond grinding wheel tool – Kemei

Quality Inspection for pore- Special shaped brazed diamond grinding wheel tool – Kemei

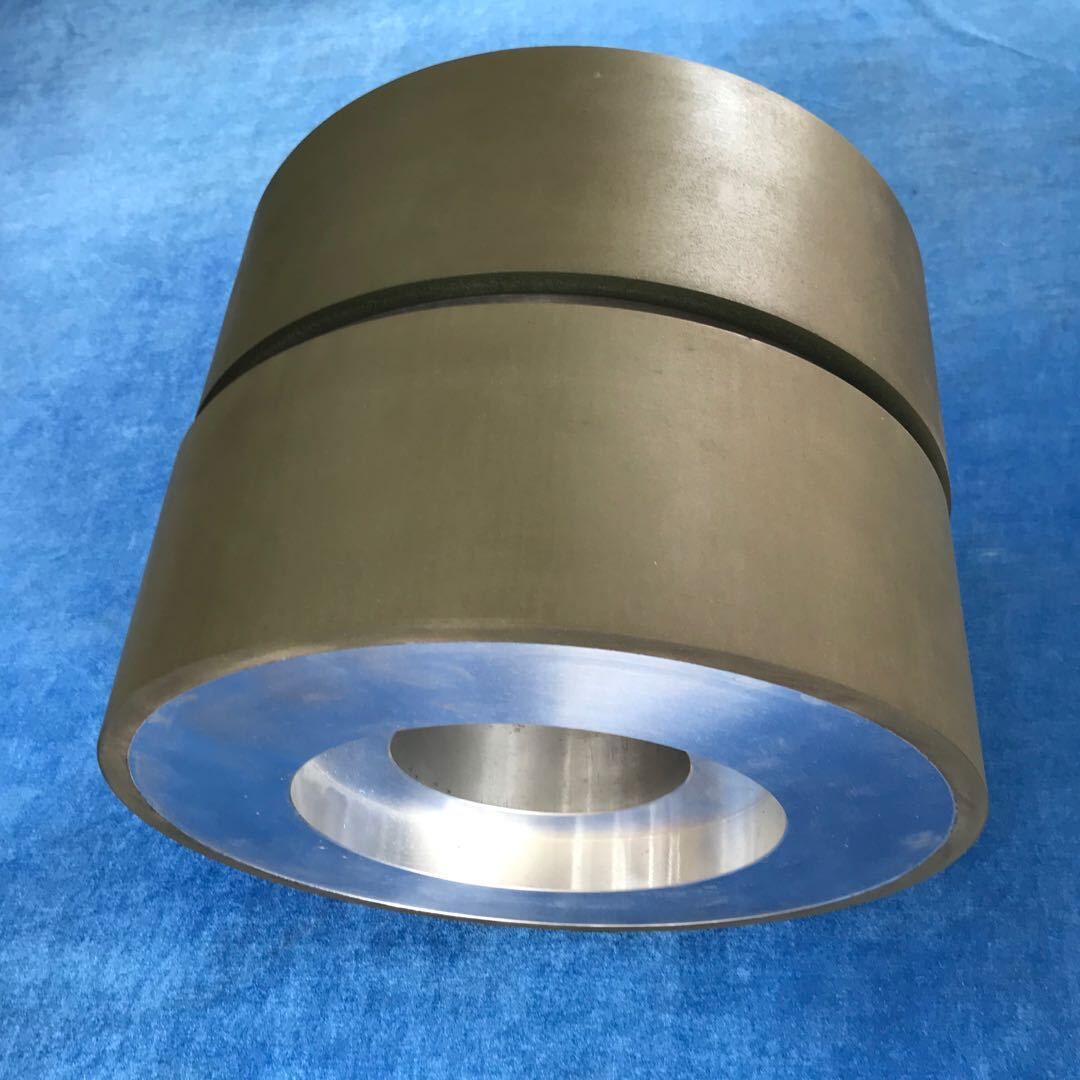

Quality Inspection for pore- Special shaped brazed diamond grinding wheel tool – Kemei Detail:

Due to the high interface energy between diamond and general metal and alloy, diamond particles can not be infiltrated by general low melting point alloy, with poor cohesiveness. In traditional manufacturing technology, diamond particles only rely on the mechanical clamping force generated by the cold shrinkage of the matrix to inlay in the metal matrix of the matrix, but not form a solid chemical bond or metallurgical bond, resulting in diamond particles It is easy to separate from matrix metal base in work, which greatly reduces the service life and performance level of diamond tools. In most impregnated tools, the utilization rate of diamond is low, and a large number of expensive diamonds are lost in the waste chips. Lin Zengdong took the lead in using diamond surface metallization technology to endow diamond surface with many new characteristics, such as excellent thermal conductivity, good thermal stability, improving its original physical and chemical properties, improving its wettability to metal or alloy solution, etc.

The metallization of diamond surface has attracted the attention of diamond tool manufacturers at home and abroad since 1970s. *** Although it has been proved that some metals such as tungsten (not oxidized) can form WC layer on the surface of diamond at a lower temperature (about 800 ℃), the ideal bonding force can be obtained by heating for 1 hour under vacuum and above 600 ℃ according to the process used to realize diamond surface pre metallization. According to the sintering conditions of the commonly used impregnated diamond cutting tools, it is unlikely that the metallized layer will be formed on the diamond surface if it is heated for about 5 minutes at 900 ℃ in non vacuum or low vacuum. Because whether the active metal atoms (Ti, V, Cr, etc.) are enriched on the diamond surface or the interface reaction reaches the metallurgical combination of bond and diamond is an atomic diffusion process. According to the temperature used for hot pressing and such a short time, this process is extremely inadequate. Under the condition of solid phase sintering (sometimes there are a small amount of low strength and low melting point metal or alloy liquid phase), the chemical bonding or metallurgical bonding force of matrix to diamond is very weak or will not form at all.

The pre metallization of diamond surface is not the ultimate goal, but only one of the measures to realize the chemical metallurgy combination with matrix metal. After the coated diamond is sintered into saw (drill) teeth, the diamond exposed on the fracture section loses the coating, and the surface of the remaining pits is very smooth, which seems to indicate that the diamond and matrix have not reached the level of chemical cladding. Therefore, even if the surface pre metallization of diamond is realized, the traditional solid-phase powder metallurgy sintering method can not realize the solid combination between diamond and matrix material.

Product detail pictures:

Related Product Guide:

We now have a specialist, efficiency workforce to deliver excellent service for our purchaser. We always follow the tenet of customer-oriented, details-focused for Quality Inspection for pore- Special shaped brazed diamond grinding wheel tool – Kemei , The product will supply to all over the world, such as: Ecuador , Benin , Curacao , What is good price? We provide customers with factory price. In the premise of good quality, efficiency must be paid attention to and maintain appropriate low and healthy profits. What is a fast delivery? We make the delivery according to customers' requirements. Although delivery time depends on the order quantity and the complexity of it, we still try to supply products in time. Sincerely hope we could have long term business relationship.

In general, we are satisfied with all aspects, cheap, high-quality, fast delivery and good procuct style, we will have follow-up cooperation!