Quality Inspection for pore- Sintered diamond cup wheel – Kemei

Quality Inspection for pore- Sintered diamond cup wheel – Kemei

Quality Inspection for pore- Sintered diamond cup wheel – Kemei Detail:

Using diamond abrasive as raw material, metal powder, resin powder, ceramic and electroplated metal as binders, a circular bonded abrasive tool with a through hole in the center is called diamond grinding wheel (alloy grinding wheel).

purpose

Due to the characteristics and advantages of diamond abrasives, diamond grinding wheels have become the preferred tool for grinding hard and brittle materials such as glass, ceramics, gemstones, stone materials and cemented carbide. With the progress of the times, the development of science, the need of the society, the development of new materials, the development of grinding to the direction of high quality, high precision, high efficiency and automation, the role of diamond wheel is more and more obvious. The metal bond diamond wheel has high holding strength, long service life and less abrasion, which makes the diamond wheel in high speed and super high efficiency and high precision In the process of grinding, the wear-resistant cutting ability is fully used, especially in the hard brittle and hard to machine materials. Diamond grinding wheel is applied in almost all fields of industry, such as aerospace, mold manufacturing, semiconductor manufacturing, optical processing manufacturing, etc. Ceramic materials, optical materials, aeroengine turbine blades, silicon products, etc. are all grinded with diamond wheel

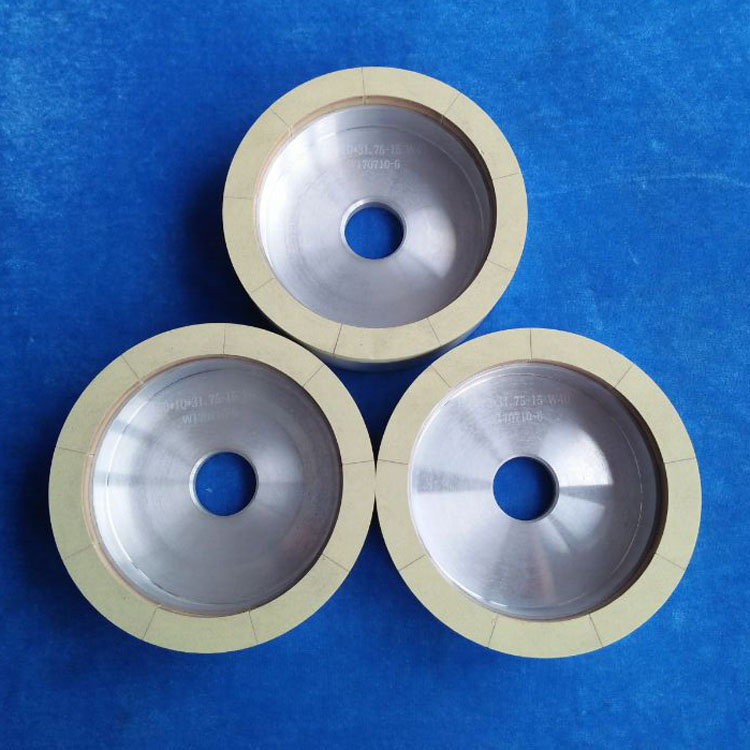

Sintered diamond wheel

Sintered metal bonded grinding wheels are mostly made of bronze and other metals by high temperature sintering. They have high bonding strength, good formability, high temperature resistance, good heat conductivity and wear resistance, long service life and can bear large load. Because of the inevitable shrinkage and deformation in the sintering process of grinding wheel, it is necessary to reshape the grinding wheel before use, but the dressing of grinding wheel is difficult. Now, the common method of grinding wheel roll shaping is not only dressing

It is time-consuming and laborious, and the diamond particles fall off a lot in the dressing process, the dressing wheel itself consumes a lot, and the shaping accuracy is low.

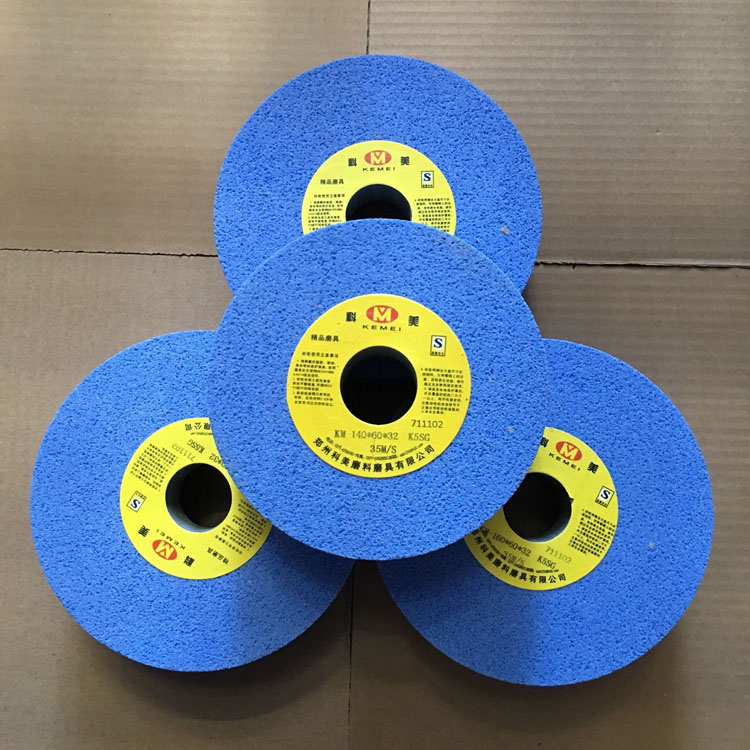

Product detail pictures:

Related Product Guide:

We keep on with our business spirit of "Quality, Performance, Innovation and Integrity". We goal to create much more worth for our customers with our rich resources, state-of-the-art machinery, experienced workers and exceptional providers for Quality Inspection for pore- Sintered diamond cup wheel – Kemei , The product will supply to all over the world, such as: Qatar , Mombasa , Bangladesh , Wide selection and fast delivery for you! Our philosophy: Good quality, great service, keep improving. We are looking forward that more and more oversea friends join in our family for further development near the future!

The goods are very perfect and the company sales manager is warmful, we will come to this company to purchase next time.