Professional Factory for diamond discs for granite - Electroplated diamond grinding wheel – Kemei

Professional Factory for diamond discs for granite - Electroplated diamond grinding wheel – Kemei

Professional Factory for diamond discs for granite - Electroplated diamond grinding wheel – Kemei Detail:

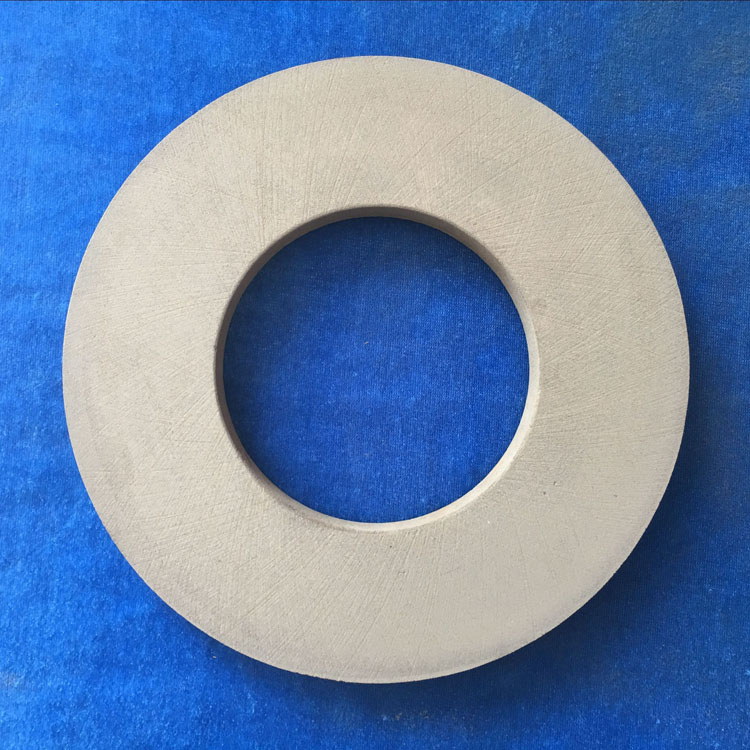

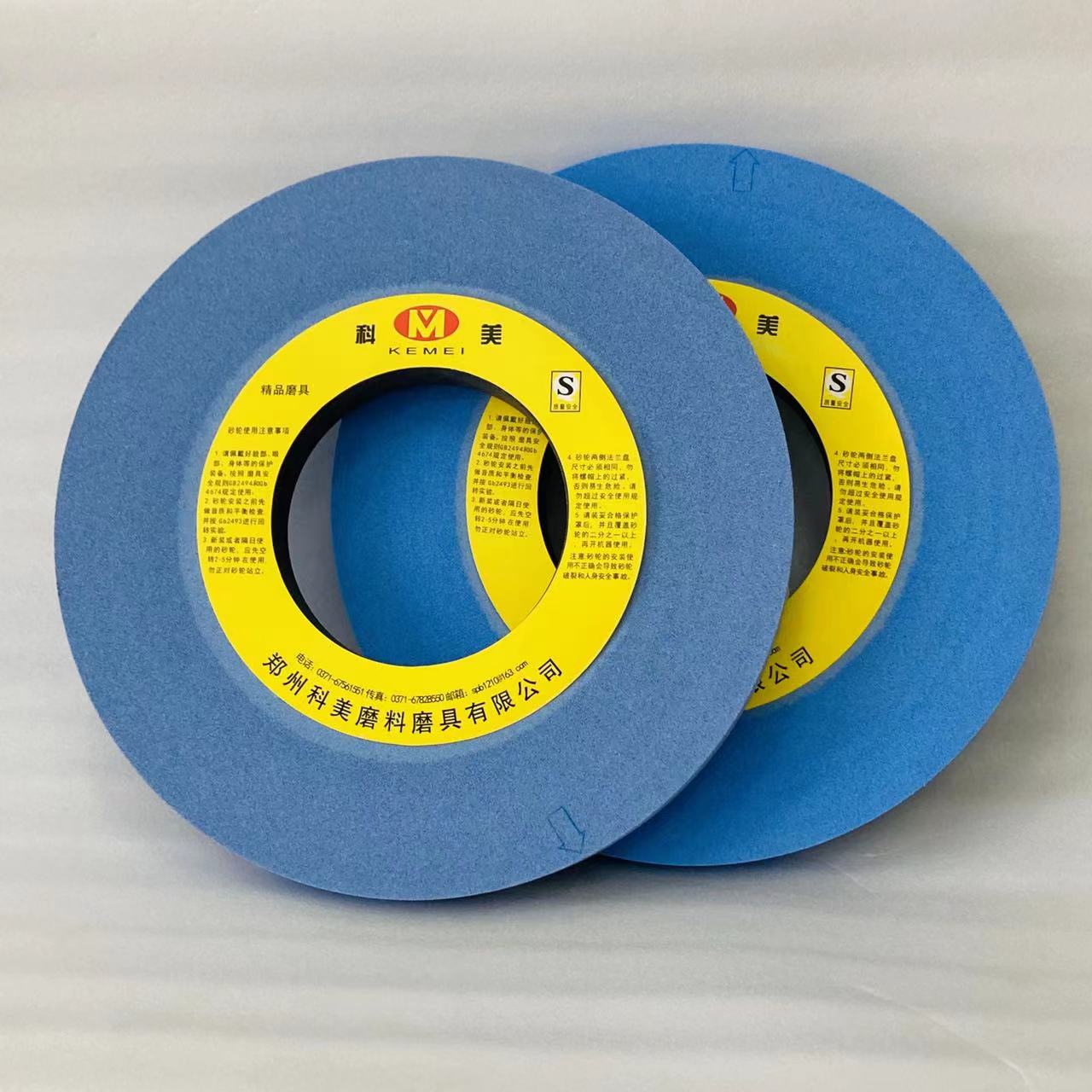

Diamond electroplated double bevel grinding wheel customized non-standard special-shaped back electroplated SDC, CBN grinding wheel cutting piece The diamond resin grinding wheel is made of high-quality diamond, which has a good polishing effect. After grinding, the product has a high aesthetic accuracy, a good self sharpening property and is not suitable for blocking. It also has a high hardness and a strong grinding ability. It is mainly used for fine grinding, semi-fine grinding, knife grinding, polishing and other processes; grinding and cutting hard and brittle cemented carbide, non-metallic materials, ceramics, agate, optical glass, cast iron, stone, tungsten steel, high-speed steel, glass, magnetic materials, measuring tool grinding tools and other plane grinding, cutting grinding and forming, grinding, coreless grinding machine and blade processing, gear hob, thread cutter forming Type. Electroplated grinding wheel can maintain stable performance in grinding accuracy, grindability and service life. They have good response in various occasions. Advantages of grinding wheel: 1. Due to the large protrusion of abrasives, without the influence of binders, the grinding ability is extremely excellent, which can be applied to many different materials processing. 2. Complex shape requirements, can be low-cost, very short-term production completed. 3. Generally speaking, because there is only one layer of abrasives with short service life, it is suitable for a small number of diversified production and processing. 4. If the matrix is metal, the abrasive particles can be electroplated on various shapes, so it can be applied not only to grinding tools, but also to various wear-resistant tools. 5. It can be recovered and reused (re plating) if the substrate is not subject to operation.

Product detail pictures:

Related Product Guide:

With our abundant experience and considerate products and services, we have been recognized to be a reputable supplier for a lot of global consumers for Professional Factory for diamond discs for granite - Electroplated diamond grinding wheel – Kemei , The product will supply to all over the world, such as: Greenland , Nicaragua , Germany , Our products are sold to the Middle East, Southeast Asia, Africa, Europe, America and other regions, and are favorably appraised by clients. To benefit from our strong OEM/ODM capabilities and considerate services, please contact us today. We will sincerely create and share success with all clients.

The goods we received and the sample sales staff display to us have the same quality, it is really a creditable manufacturer.