PriceList for grinding wheel- CBN cutting disc/Slotting saw blade/High vanadium high speed steel cutting wheel – Kemei

PriceList for grinding wheel- CBN cutting disc/Slotting saw blade/High vanadium high speed steel cutting wheel – Kemei

PriceList for grinding wheel- CBN cutting disc/Slotting saw blade/High vanadium high speed steel cutting wheel – Kemei Detail:

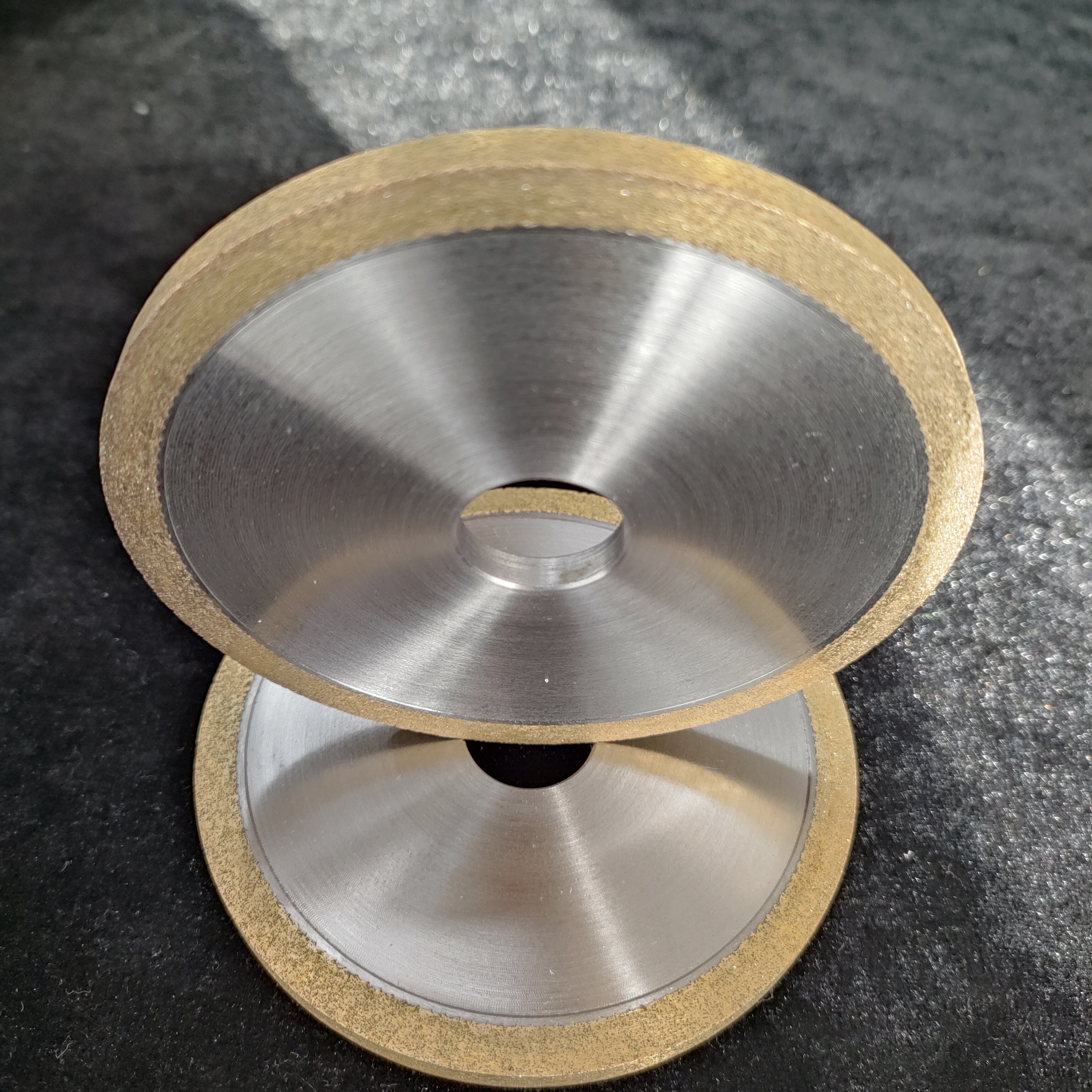

Product Name:Resin CBN Cutting Disc

Bond:Resin

Abrasive material:CBN

Applied to:It is used for cutting and grooving the steels parts.

Production time:7 days

Model size:150*2*50mm

Features:1.150% CBN concentration

2.More efficiency

3.Long service time

When grinding various grades of high-speed steel, the abrasive must have:

(1) The hardness must be higher than the hardness of the carbide which accounts for a large proportion in the high-speed steel being ground.

(2) In the process of grinding high temperature and severe extrusion, the abrasive should have certain strength and toughness.

When grinding wheels with different abrasives, the results obtained are different when grinding various new high-speed steels. It can be seen that the grindability of high-speed steel with vanadium content of about 1% and 2% is better than that of high-vanadium high-speed steel with vanadium content of 3% and 4%. Under the same grinding conditions, the grinding performance of the single crystal corundum wheel is better than that of the Cuqin corundum, which is due to

The single crystal corundum abrasive has a medium volume and a multi-angular cutting edge, so the abrasive cutting edge has a long life, and the grinding amount is large over time. The grinding wheel wears less, the grinding ratio is high, and the geometric shape retention performance is good. However, the proportion of isocratic abrasive grains in Cochin corundum abrasives is small, and there are many needle-shaped abrasive grains. The abrasive grains are easy to break during grinding, the cutting edge is difficult to maintain, and the grinding wheel wears large. When using cubic boron nitride (CBN) abrasives to grind high-speed steel with a vanadium content of 2%, the grinding ratio is 4 to 7 times higher than that of single crystal corundum. Especially when the vanadium content of the workpiece material is 3% and above, it shows the superiority of cubic boron nitride abrasive. Its grinding ratio is 5-30 times higher than that of single crystal corundum and 15-40 times higher than that of complex-sensitive corundum.

Product detail pictures:

Related Product Guide:

We are convinced that with joint endeavours, the small business between us will bring us mutual benefits. We could assure you products quality and competitive selling price for PriceList for grinding wheel- CBN cutting disc/Slotting saw blade/High vanadium high speed steel cutting wheel – Kemei , The product will supply to all over the world, such as: Belgium , Swansea , Naples , We aspire to meet the demands of our customers globally. Our range of products and services is continuously expanding to meet customers' requirements. We welcome new and old customers from all walks of life to contact us for future business relationships and achieving mutual success!

In China, we have purchased many times, this time is the most successful and most satisfactory, a sincere and realiable Chinese manufacturer!