Original Factory magnesia grindstone- Electroplated diamond roller special-shaped electroplated CBN grinding wheel – Kemei

Original Factory magnesia grindstone- Electroplated diamond roller special-shaped electroplated CBN grinding wheel – Kemei

Original Factory magnesia grindstone- Electroplated diamond roller special-shaped electroplated CBN grinding wheel – Kemei Detail:

1.Simple operation, high dressing efficiency, long service life, stable quality, easier to achieve automation;

2.The grinding wheel with complex profile which can not be finished by other dressing methods can be trimmed, and the surface quality and accuracy are stable;

3.The angle symmetry tolerance of diamond dressing roller is controlled within 0.5 degree, and the minimum tolerance of arc is guaranteed within 2 μ M.

4.”Tailor-made” service, standardized process, value exceeding contract created for customers

Precautions for use

(1).Do not give the roller a strong impact.

(2).The radial runout at the roller step after installation shall not exceed 0.004

(3).Do not press the on / off button when the grinding wheel and roller contact (only after stopping)

(4).Before dressing, the roller and the grinding wheel must be cooled for a certain period of time with coolant. The flow rate and pressure of the coolant during dressing should be equal to that during grinding.

(5).During dressing, the contact part with grinding wheel shall be fully filled with coolant.

(6).The rotating part of the drive must not enter dirt.

(7).The fit clearance between roller and mandrel shall be controlled within 0.004 to prevent vibration.

(8).During roller trimming, each feeding amount shall not exceed 0.02

Our company, as the leader of precision and ultra precision grinding tools, combines foreign honing technology, advanced technology and high-end equipment in Europe and America, and cooperates with domestic well-known grinding tool research and development institutions. Its high-precision diamond reamer and diamond roller are widely used in the fields of automobile, hydraulic pressure, bearing, machine tool, aerospace and military industry

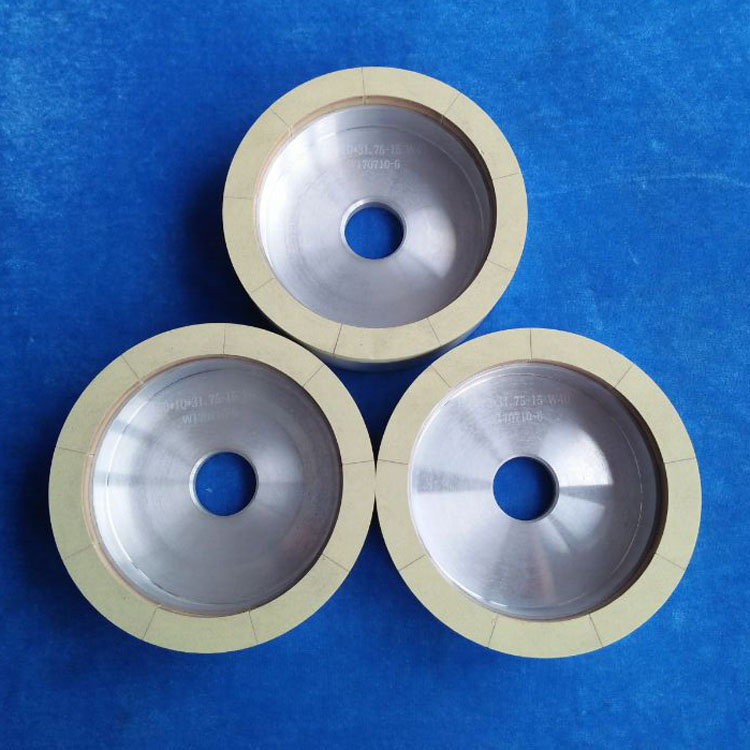

Product detail pictures:

Related Product Guide:

Our commission is to serve our buyers and purchasers with most effective good quality and aggressive portable digital goods for Original Factory magnesia grindstone- Electroplated diamond roller special-shaped electroplated CBN grinding wheel – Kemei , The product will supply to all over the world, such as: Victoria , Saudi Arabia , Slovakia , If any product meed your demand, please feel free to contact us. We're sure your any inquiry or requirement will get prompt attention, high-quality products, preferential prices and cheap freight. Sincerely welcome friends all over the world to call or come to visit, to discuss cooperation for a better future!

The customer service staff's attitude is very sincere and the reply is timely and very detailed, this is very helpful for our deal,thank you.