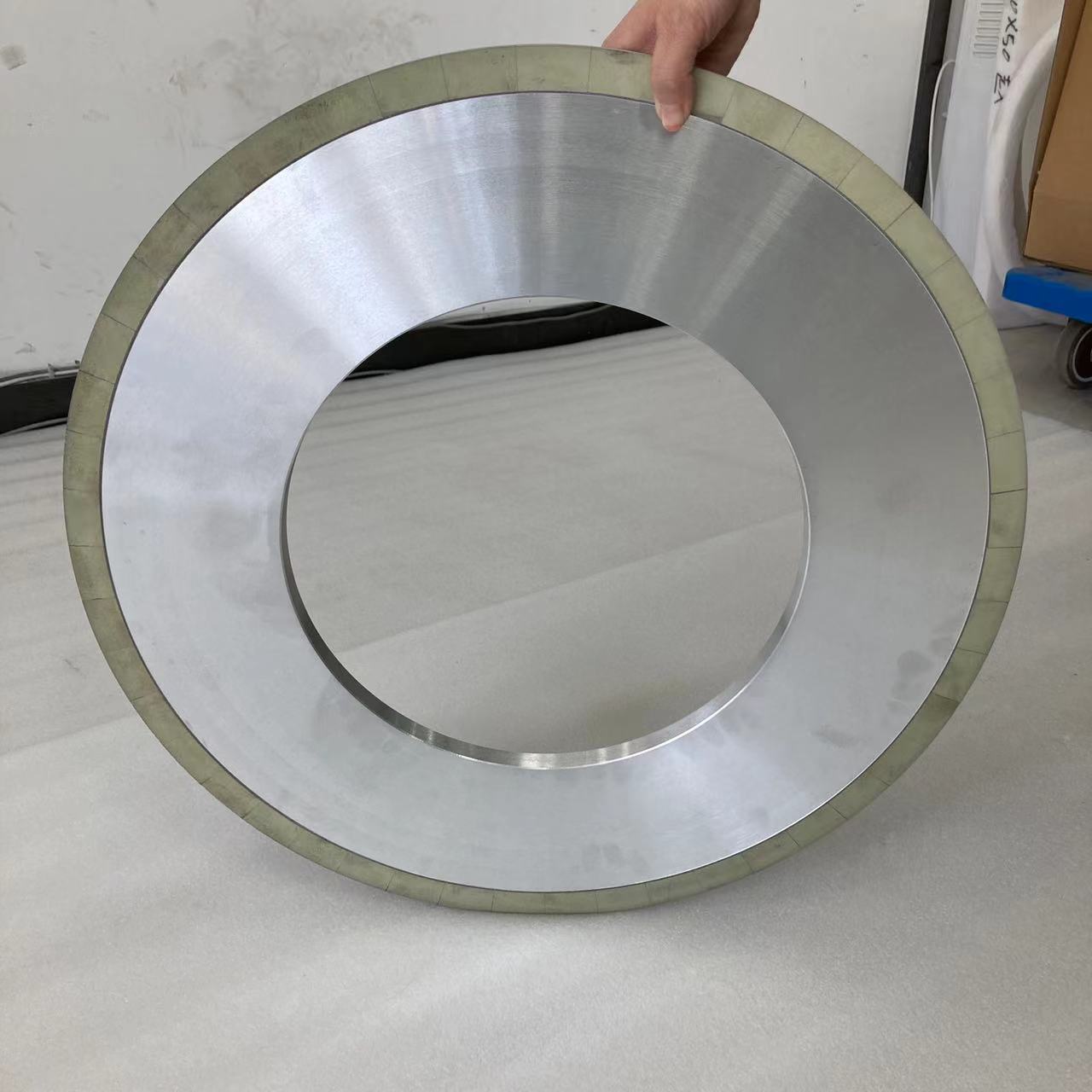

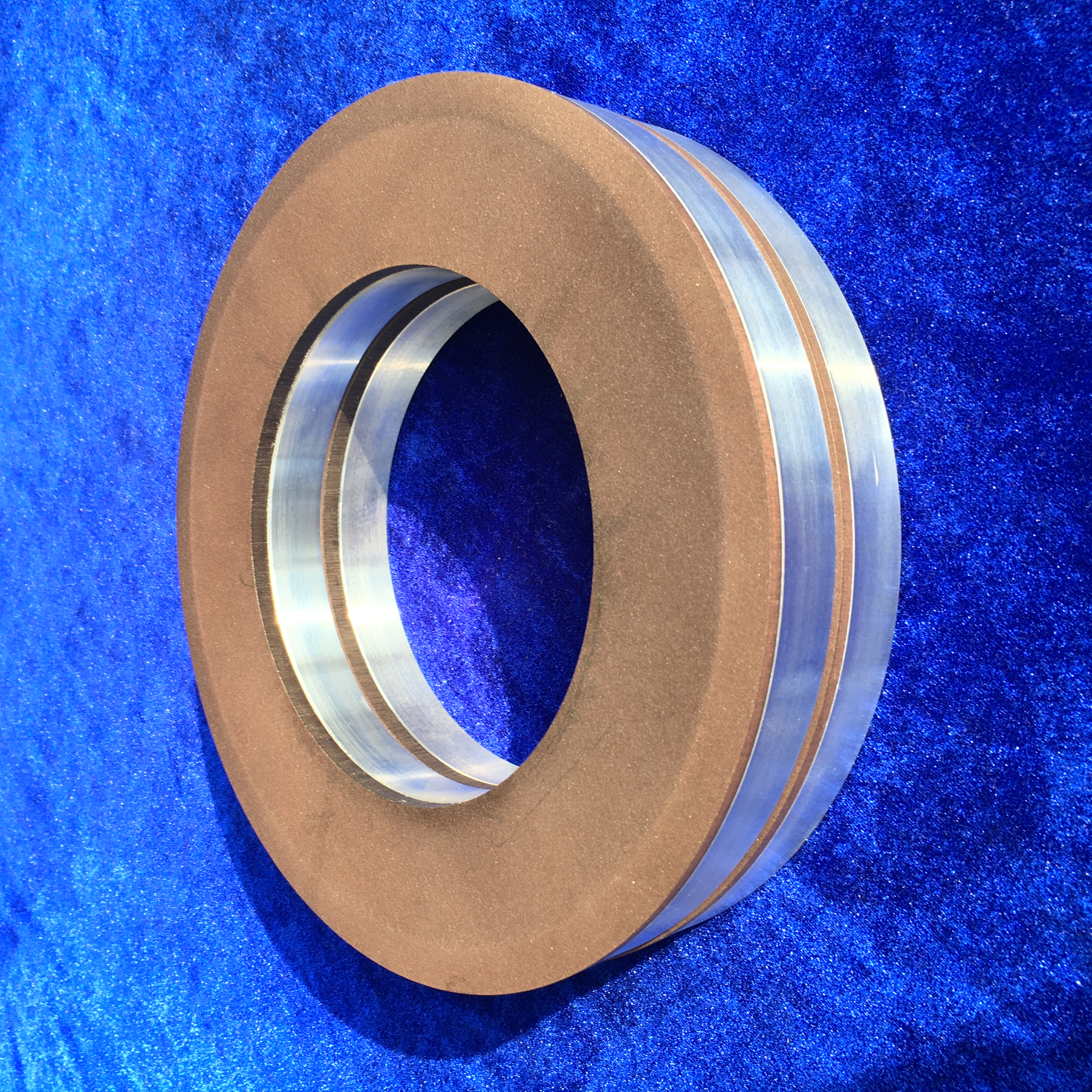

OEM/ODM China pvc Polishing wheel- Grinding head of special polishing wheel for aluminum alloy and titanium alloy – Kemei

OEM/ODM China pvc Polishing wheel- Grinding head of special polishing wheel for aluminum alloy and titanium alloy – Kemei

OEM/ODM China pvc Polishing wheel- Grinding head of special polishing wheel for aluminum alloy and titanium alloy – Kemei Detail:

This grinding head is made of abrasive cloth impeller, commonly used grain No. 60 #, 80 #, 120 #, 180 #, 240 #, 320 #, 400 #. It is used in conjunction with electric and pneumatic tools and is suitable for metal And non-metallic products with inner and corner treatment. Common specifications: 50 (diameter) X25 (thickness) X6 (shank diameter) 0.2–0.3 USD / piece, 40 (diameter) X25 (thickness) X6 (shank diameter) 0.15–0.25 USD / piece, 30 (diameter) X25 (Thickness) X6 (shank diameter) 0.1-0.2 USD / piece, diameter range: 20 — 80mm

Features:

It is 100% brand new and high quality.

Suitable for deep hole polishing and finishing on the surface of wood,plastic,metal and non-metallic complex surface.

Particularly applicable for grinding and polishing on surface and its side face.

Supporting used with straight grinder, hand drill, pneumatic tool, electric drill, pneumatic drill, bench drill, etc.

Sharp grinding, strong grinding power, solid and durability, long life, high tensile strength cloth, high efficiency.

Advantage:

1Suitable for automatic and superpower & high rotation speed equipment, comprehensive process efficiency promotes 40%;

2.Comprehensive longevity lengthens to above 35 times, it can be continuous working, reduce the process interval time;

3. Safe, no crack pieces.

4. No dust, no smell,protect the environment.

5. Maintain the processing accuracy, no change in outer diameter.

6. Suits for various material, such as metal, stone, composite materials.

Application:Gray iron,ductile iron and other iron casting parts’ inner wall, corner, grinding,and deburring.

Good Performance: Suitable for both grinding and polishing, it is not burnt the work piece after any process. Fit for Rotary Tools: Can be used with electric drills, electric grinders or other rotary tools.

Product detail pictures:

Related Product Guide:

abide by the contract", conforms into the market requirement, joins in the market competition by its good quality also as provides a lot more comprehensive and great company for purchasers to let them turn into huge winner. The pursue from the firm, would be the clients' gratification for OEM/ODM China pvc Polishing wheel- Grinding head of special polishing wheel for aluminum alloy and titanium alloy – Kemei , The product will supply to all over the world, such as: Hamburg , Roman , Mozambique , Many years of work experience, we have realized the importance of providing good quality products and the best before-sales and after-sales services. Most problems between suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question things they do not understand. We break down those barriers to ensure you get what you want to the level you expect, when you want it. faster delivery time and the product you want is our Criterion .

The company's products can meet our diverse needs, and the price is cheap, the most important is that the quality is also very nice.