OEM Supply form grinding wheel- CERAMIC DIAMOND GRINDING WHEEL AND GRINDING HEAD – Kemei

OEM Supply form grinding wheel- CERAMIC DIAMOND GRINDING WHEEL AND GRINDING HEAD – Kemei

OEM Supply form grinding wheel- CERAMIC DIAMOND GRINDING WHEEL AND GRINDING HEAD – Kemei Detail:

CBN grinding wheel for steel grinding

Artificial synthesis production: covalently connected cubic boron nitride, CBN is the second hard material, and the hardness is about hv4500. CBN has high thermal conductivity and chemical stability, which makes it suitable to process steel materials and obtain high cutting performance in grinding process. In order to give full play to the potential of CBN, using high cutting speed is the basic requirement of CBN wheel. Many kinds of CBN lead us to provide different applications according to the situation of grinding wheel. Steel, nickel base alloy or high speed steel: CBN is always the right grinding material you can choose.

*High speed steel shrinkage written as HS meets the new standard (EN ISO 4957)CBN or diamond

Abrasive is the best choice for large cutting and high cutting speed. It can be used for rough and finish machining. High efficiency can be obtained without dressing.

Forming roller with single axial feed

Single axial feed forming rollers are usually used for dressing many different kinds of grinding wheels for mass production. Shorter dressing time and longer tool life lead to high efficiency of production and consistency of technology. All kinds of common grinding wheels and special superhard grinding wheels can be dressed by this method. CD dressing (continuous dressing) is often used for dressing hardened workpieces and precision formed grinding wheels of super heat-resistant stainless steel. For various dressing applications, Dr. Kaiser can provide dressing tools for specific applications to achieve the required tolerance and tool life.

It is used in many applications: screw, blade, support journal, bearing channel, valve, engine valve, fuel injection component.

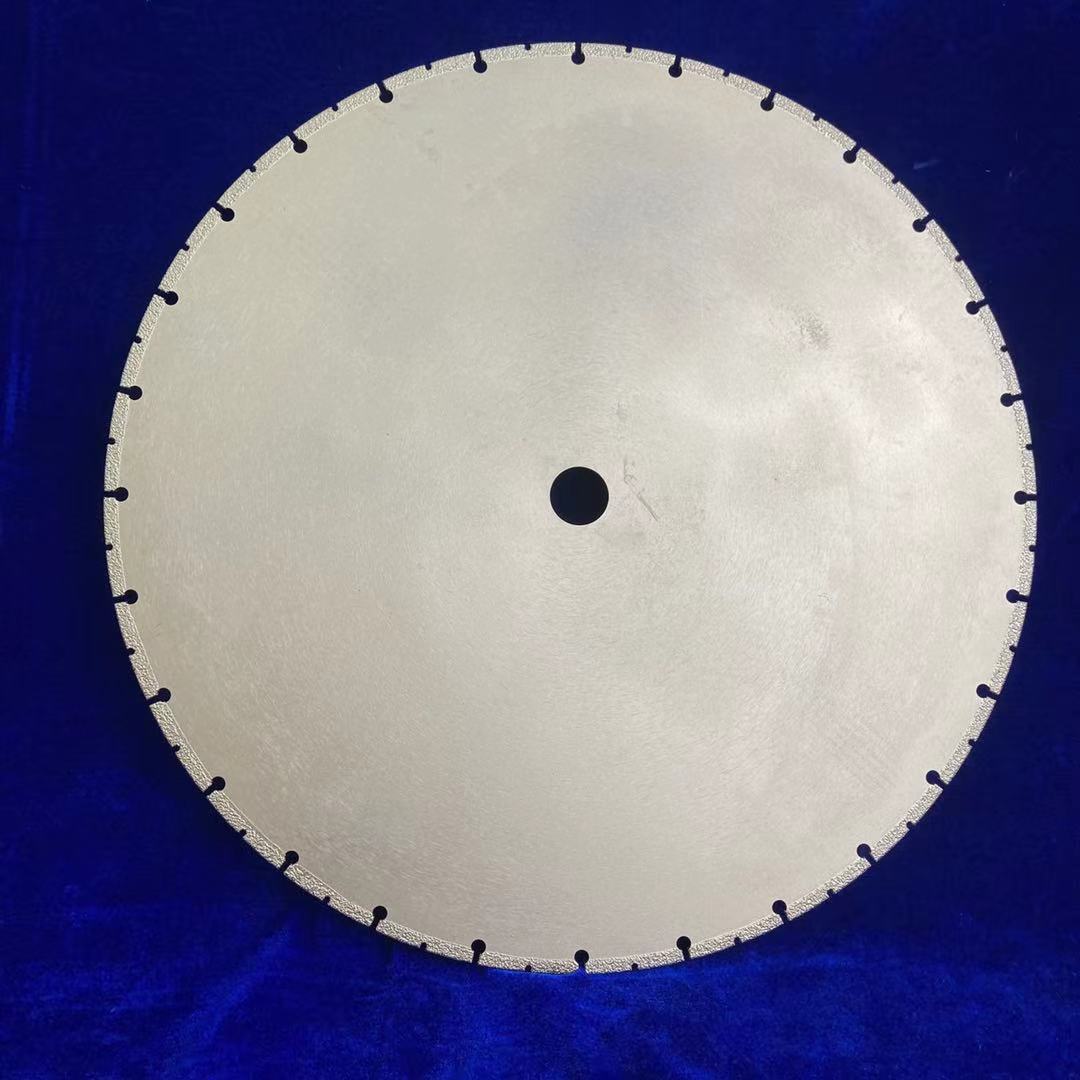

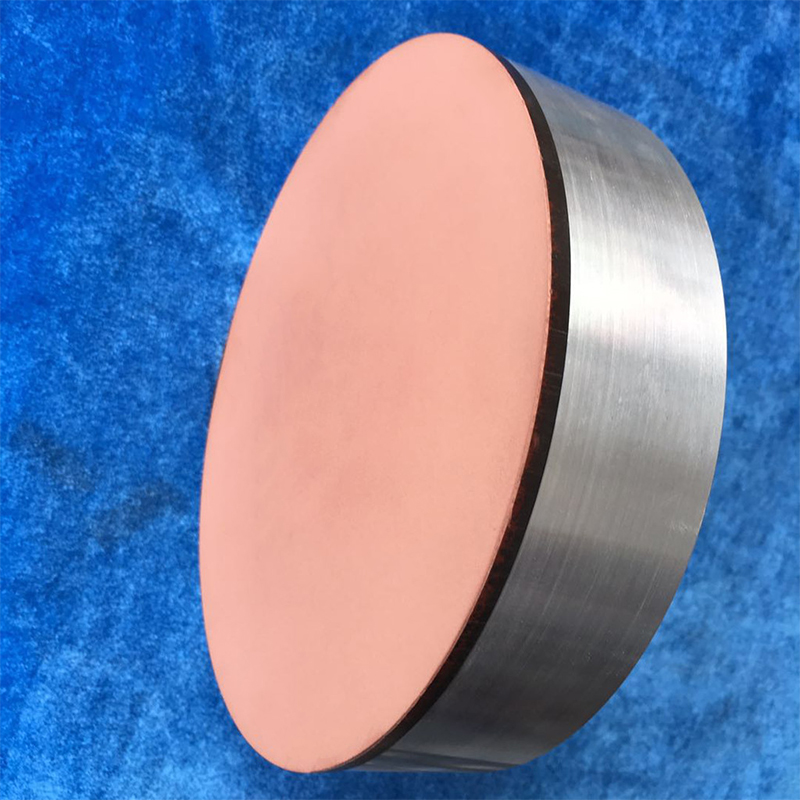

Product detail pictures:

Related Product Guide:

Assume full duty to satisfy all demands of our clients; reach steady advancements by marketing the development of our purchasers; grow to be the final permanent cooperative partner of clientele and maximize the interests of customers for OEM Supply form grinding wheel- CERAMIC DIAMOND GRINDING WHEEL AND GRINDING HEAD – Kemei , The product will supply to all over the world, such as: New Zealand , Islamabad , Bolivia , More than 26 years, Professional companies from all over the world take us as their long-term and stable partners. We are keeping durable business relationship with more than 200 wholesalers in Japan, Korea, USA, UK, Germany, Canada, France, Italian, Poland, South Africa, Ghana, Nigeria etc.

As a veteran of this industry, we can say that the company can be a leader in the industry, select them is right.