ODM Manufacturer abrasive cutting disc- All kinds of small grinding wheels and small grinding heads for dentistry and Dentistry – Kemei

ODM Manufacturer abrasive cutting disc- All kinds of small grinding wheels and small grinding heads for dentistry and Dentistry – Kemei

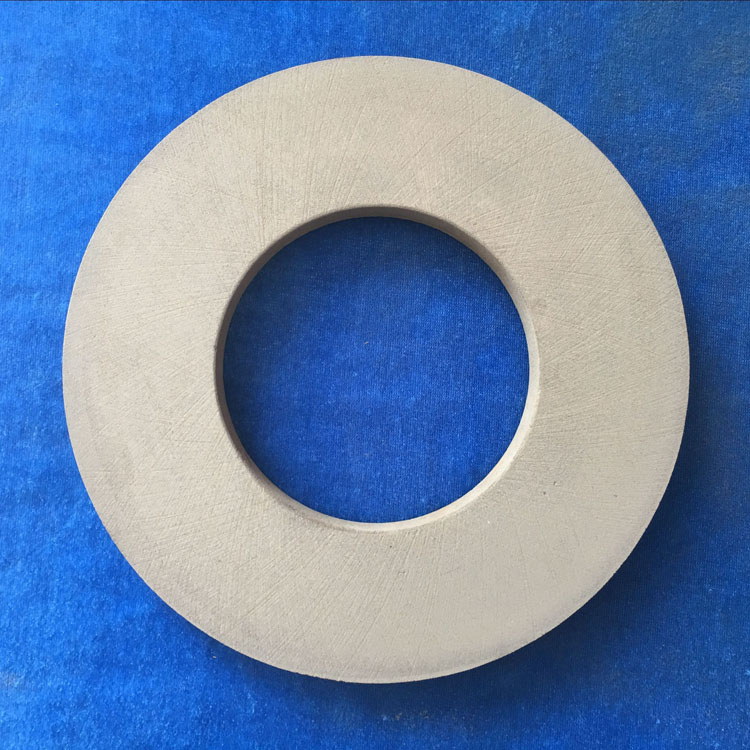

ODM Manufacturer abrasive cutting disc- All kinds of small grinding wheels and small grinding heads for dentistry and Dentistry – Kemei Detail:

Rubber grinding head: the finer grain size sand is synthesized by the combination of rubber bond and used for the polishing of mould.

Application Description: used for grinding and polishing of porcelain teeth, light curing resin, resin, precious metal and natural teeth

Features: using imported silica gel, silicon carbide and other raw materials, with good elasticity, high concentricity, no heating, no blackening, high temperature resistance, stable rotation speed and other points, more fine and durable.

This grinding head is divided into various specifications according to the diameter and shape of the head. If you need to buy it, please indicate the diameter and shape of the grinding head. If you need more details and product specification table, please contact our sales personnel.

Scope of application:

The products can be used for grinding hard alloy, chromium cobalt alloy, silver amalgam, precious metal, gold, copper, synthetic resin, ceramics, enamel, other metal, non-metal and other materials.

Dental clinic / precious metal / ceramic / resin special silicon rubber grinding head of various models can be produced by our company. Welcome new and old customers to come for consultation and discussion.

Product features:

1. It is elastic and has good polishing performance. It can easily make the surface roughness of workpiece reach △ 0.2 ~△ 0.1. According to the different grinding objects, our company has three different types of products for users to choose: soft rubber grinding head, hard rubber grinding head and semi-hard rubber grinding head

2. It has high mechanical strength, good tensile and seismic resistance. The tensile strength can reach 68 MPa, bending strength can reach 98 MPa, and impact strength can reach 0.15 Joule / cm2. Therefore, the rubber grinding head produced by our company can generally be used in the linear speed of 40-50 M / s. if the matching side is slightly adjusted, it can reach 50-60 M / s

The rubber grinding head produced by our company not only has good grinding surface quality, but also has good wear resistance

Product detail pictures:

Related Product Guide:

Using a total scientific good quality management process, superior high quality and excellent faith, we get great name and occupied this field for ODM Manufacturer abrasive cutting disc- All kinds of small grinding wheels and small grinding heads for dentistry and Dentistry – Kemei , The product will supply to all over the world, such as: Lyon , Swaziland , Argentina , Faced with the vitality of the global wave of economic integration, we've been confident with our high-quality items and sincerely service to all our customers and wish we can cooperate with you to create a brilliant future.

We feel easy to cooperate with this company, the supplier is very responsible, thanks.There will be more in-depth cooperation.