Low MOQ for diamond dressing roller- Special sintered diamond cutting piece for ceramic Cu-W alloy – Kemei

Low MOQ for diamond dressing roller- Special sintered diamond cutting piece for ceramic Cu-W alloy – Kemei

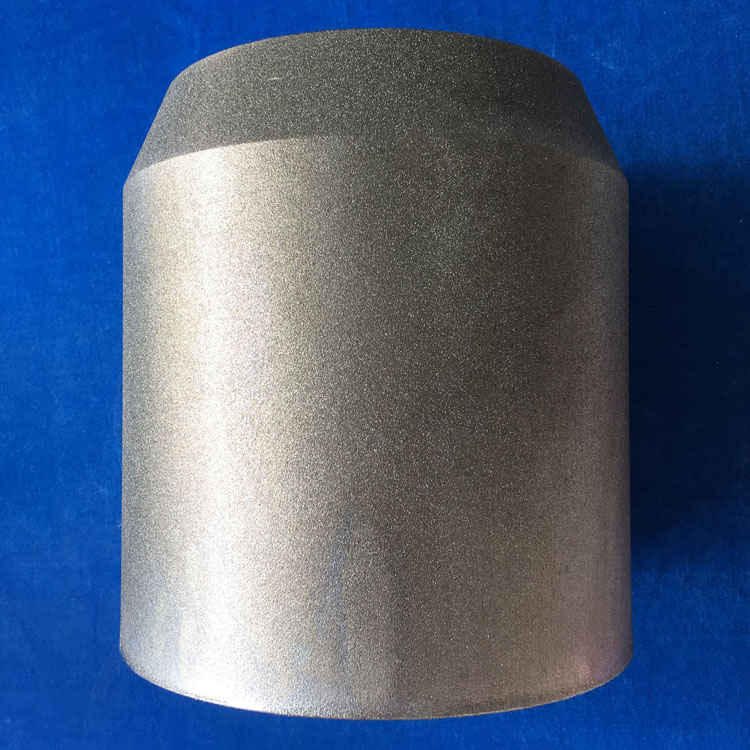

Low MOQ for diamond dressing roller- Special sintered diamond cutting piece for ceramic Cu-W alloy – Kemei Detail:

Diamond cutting is a kind of cutting tool, which is widely used in the processing of hard and brittle materials such as stone, concrete, precast slab, new and old roads, ceramics, etc. diamond cutting blade mainly consists of two parts: matrix and cutter head. Matrix is the main supporting part of binding cutter head, while cutter head is the part that starts cutting in the process of use, and cutter head will be consumed continuously in use, while matrix will not, The reason why the cutting head can play the role of cutting is that it contains diamond. As the most hard material at present, diamond rubs and cuts the processed object in the cutting head, while the diamond particles are wrapped in the inside of the cutting head by metal.

Cutting speed of diamond cutting blade

The feed speed is the feed speed of the stone being sawed. Its size affects the sawing rate, the force on the saw blade and the heat dissipation in the sawing area. Its value should be selected according to the nature of the stone to be sawed. Generally speaking, the cutting speed of soft stone, such as marble, can be increased properly. If the cutting speed is too low, it is more conducive to improve the cutting rate. If the cutting speed is too low, the diamond edge is easy to be polished. However, when sawing the granite with coarse grain structure and uneven hardness, the cutting speed should be reduced, otherwise the vibration of the saw blade will lead to diamond fragmentation and reduce the cutting rate. The cutting speed of sawing granite is generally selected in the range of 9m-12m / min.

Product detail pictures:

Related Product Guide:

Our advancement depends on the superior gear ,superb talents and consistently strengthened technology forces for Low MOQ for diamond dressing roller- Special sintered diamond cutting piece for ceramic Cu-W alloy – Kemei , The product will supply to all over the world, such as: Oslo , Luxembourg , Latvia , Our Company has professional engineers and technical staff to answer your questions about maintenance problems, some common failure. Our product quality assurance, price concessions, any questions about the products, Please feel free to contact us.

In China, we have purchased many times, this time is the most successful and most satisfactory, a sincere and realiable Chinese manufacturer!