IOS Certificate compressive strength- Resin PVA sponge polishing wheel – Kemei

IOS Certificate compressive strength- Resin PVA sponge polishing wheel – Kemei

IOS Certificate compressive strength- Resin PVA sponge polishing wheel – Kemei Detail:

Characteristics of PVA grinding wheel:

1. The main component of the structure is the use of special resin to avoid the phenomenon of easy heating. PVA sponge grinding wheel is usually dry grinding.

2. The bond is soft and gentle, and there is no deep defect on the grinding surface. It can get even and beautiful bright surface.

3. Because the structure of the grinding wheel is combined by special resin, not only the wear resistance and grinding force can be enhanced, but also the grinding wheel structure can quickly remove the debris due to the existence of special pores, so that the packing and heat can not occur, which is suitable for long-term grinding work.

Application:

1. PVA grinding wheel is effective when it is applied to soft materials, which are easy to generate heat energy and block materials that are not easy to grind. For example, stainless steel, aluminum, copper, brass, titanium, alloy steel, wood, glass, stone and plastic products are specially designed to achieve an excellent degree of polishing (mirror polishing can be achieved), as well as to reduce the time of precision processing and reduce the process. It is a suitable elastic grinding wheel for mechanization and automation. The case, stainless steel tube, stainless steel plate, cutter and scissors are used to grind away the welding parts in the wheel rim of the motorcycle and remove the paint defects of the car body. The titanium drum, stainless steel sink, titanium metal roller, roller glass and various metal molds of marble jewelry (gold / Silver / platinum) are used for copper foil. Characteristics of mirror polishing wheel: 1. Grinding and polishing once completed. 2. Shorten the grinding time and achieve the surface roughness in a short time. 3. The surface of the workpiece presents the original metal color of “platinum bright”. 4. Stainless steel plate, copper, aluminum and titanium alloy are not stained with silk overnight and easy to be blocked during grinding. 5. The surface of the workpiece shall be free of scratches and pockmarks. 6. Reduce the number of grinding wheel, light weight, easy to install, and reduce the installation time.

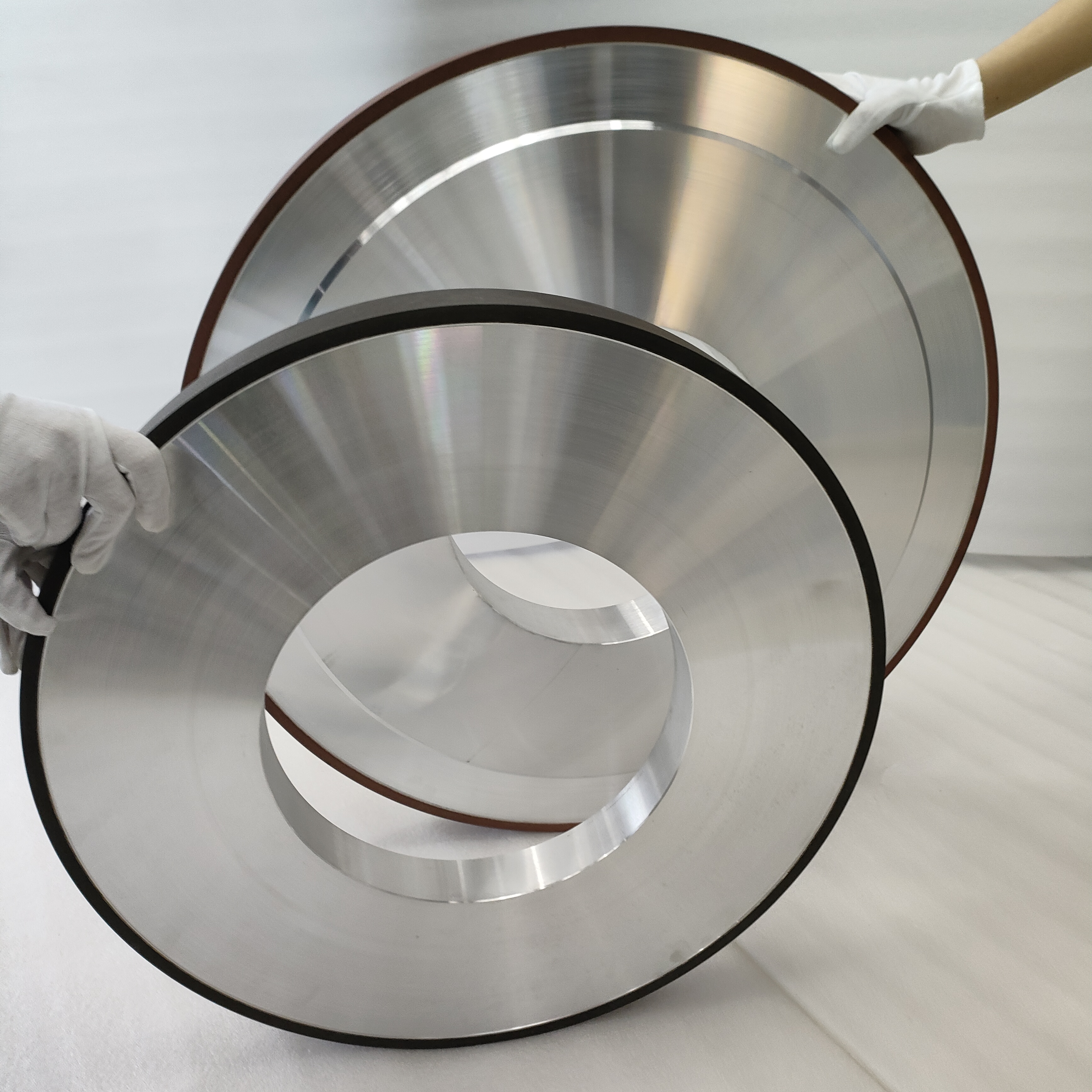

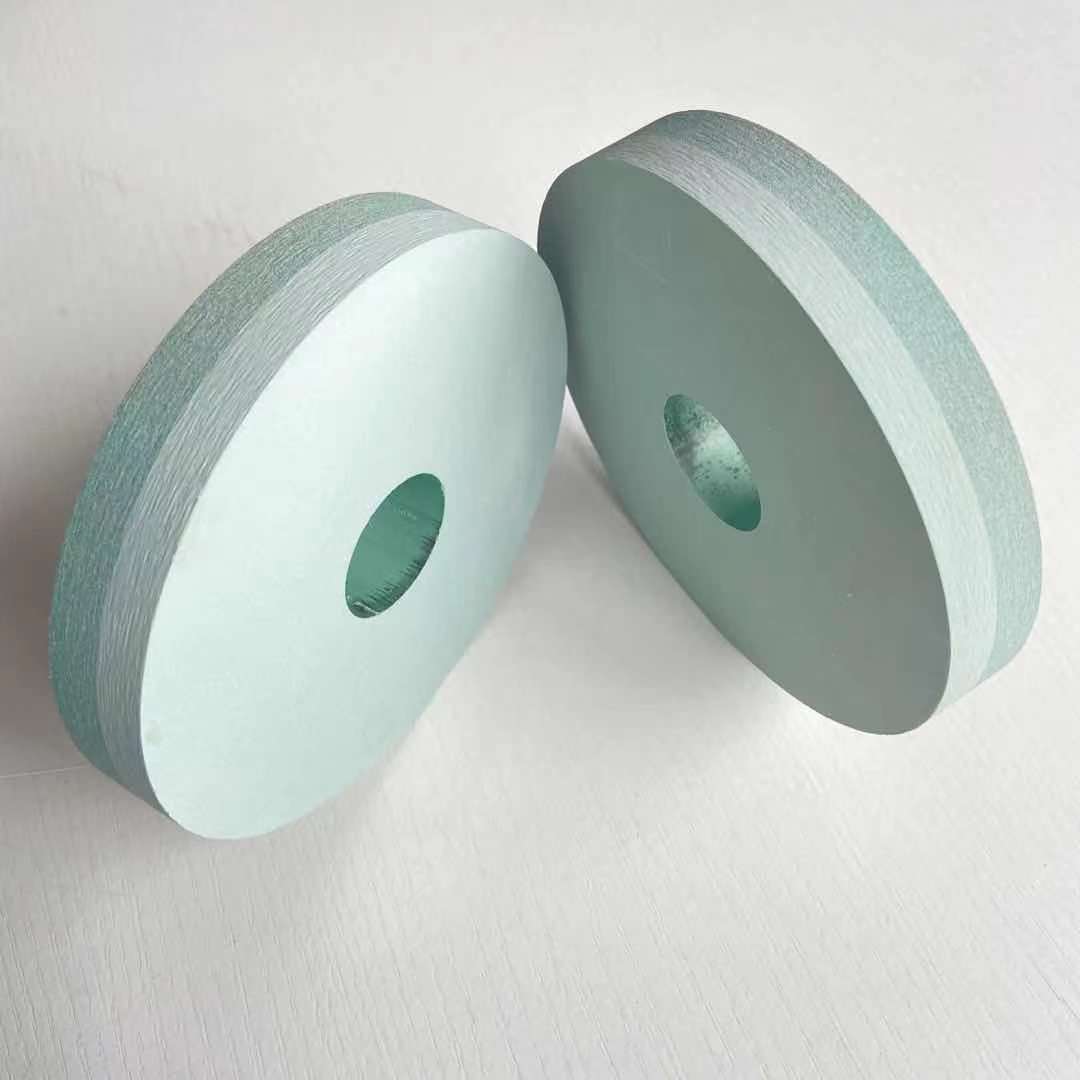

Product detail pictures:

Related Product Guide:

During the past few years, our business absorbed and digested state-of-the-art technologies the two at home and abroad. Meanwhile, our firm staffs a group of experts devoted to your development of IOS Certificate compressive strength- Resin PVA sponge polishing wheel – Kemei , The product will supply to all over the world, such as: Oslo , Suriname , Panama , We set a strict quality control system. We have return and exchange policy, and you can exchange within 7 days after receive the wigs if it is in new station and we service repairing free for our products. Please feel free to contact us for further information if you have any questions. We are glad to work for every client.

The customer service reprersentative explained very detailed, service attitude is very good, reply is very timely and comprehensive, a happy communication! We hope to have a opportunity to cooperate.