Hot sale Factory porcelain diamond blade 300mm - Diamond cutting disc for cutting jade/agate – Kemei

Hot sale Factory porcelain diamond blade 300mm - Diamond cutting disc for cutting jade/agate – Kemei

Hot sale Factory porcelain diamond blade 300mm - Diamond cutting disc for cutting jade/agate – Kemei Detail:

About the product:

|

Name: |

ultra thin diamond cutting disc, sintered cutting disc, metal bond cutting wheel, ultra thin diamond slotted disc |

|

Material |

complete diamond coated, sintering metal bonded |

|

Shape |

flat |

|

concentration |

100% |

|

Grit |

M5/10, 10/15µm |

|

Wheel diameter |

58mm 2inch |

|

Hole thread size |

40mm 1 1/2 inch |

|

Overall thickness |

0.04mm |

|

Diamond working layer |

9mm |

|

Max.Speed |

39534rpm 120m/s |

|

Features |

all diamond working layer, |

|

top-level metal bonded with diamond processing |

|

|

high quality,high-precision, and long service life |

|

|

Application |

high-precision on : ceramic, stone, glass, jade, crystal, agate |

|

Grinding type |

Wet/dry both ok |

Metal Bond Diamond Tools provide

-

Intricate Designs Complex forms can be created, and since wear rates are low they last longer than in other types.

-

Impervious to Alkaline Coolants, Unlike resin grinding wheels which are susceptible to chemical attack—especially at elevated temperatures, metal bond’s impervious properties make it well-suited for use with grinding fluids.

-

Heat quickly dissipates through the metal core This property makes metal bond appropriate for high material removal rate operations like creep feed grinding, which are also helped by the ability to use coolant.

-

Superior form holding, impact resistance With excellent hardness and wheel retention properties, metal bond performs outstanding interrupted cuts while retaining the tool’s original dimensions during everything from light polishing to the most aggressive CNC grinding actions including centerless, cylindrical, creep feed, deburring, and cutoff applications.

-

Compatible with many materials Because metal bond grinding wheels are sintered with cobalt, copper, mill, silver or sternum power, they work exceptionally well on glass, refractories, ceramics, silicon, semi-conductors, quartz, and a variety of other surfaces.

Specialties & Customed Production

KEME Grinding wheels combine a steel core with a 1/4″ diamond section, with the abrasive material and hardness tailored to your specific application requirements, making them the perfect choice for heavy stock removal with superior form holding, long life and low maintenance.

we can make the only diamond grinding wheel for you, based on your applications and special requirement.

If you have special needs on the product, leave us the following information:

If have special applications, leave us the following information:

|

shape |

size |

working layer width |

|

bond/binding agent/adhesive |

Abrasive grain |

grit designation |

|

diamond concentration |

dry /wet grinding |

|

Or tell us the product or material you want to work on or your applications, then we can provide you the professional suggestions.

What you may concern:

1: Are you a factory?

Yes, we are the producer. Our main products are diamond tools, grinding wheels, cut-off discs, sanding belts, oil stones, mounted points, etc.

2, Can I get free samples?

Yes, within 20USD samples, we can provide for free, but the shipping cost should be covered by the customers.

3, How to confirm the quality?

We have the most experienced technicians and producers. You can send us the technical parameters of the product and we will produce according to your requirements. You can ask for a sample for free. You can have a pilot order, after you confirm the product, then you can release a normal order.

4, What about quality control?

We are using the highest quality components & an efficient manufacturing process. We have the strictest QC process. We are proving a high level of service for customers and distributors. We are trying to nail down the quality complaint to zero. We will make you an enjoyable experience working with us.

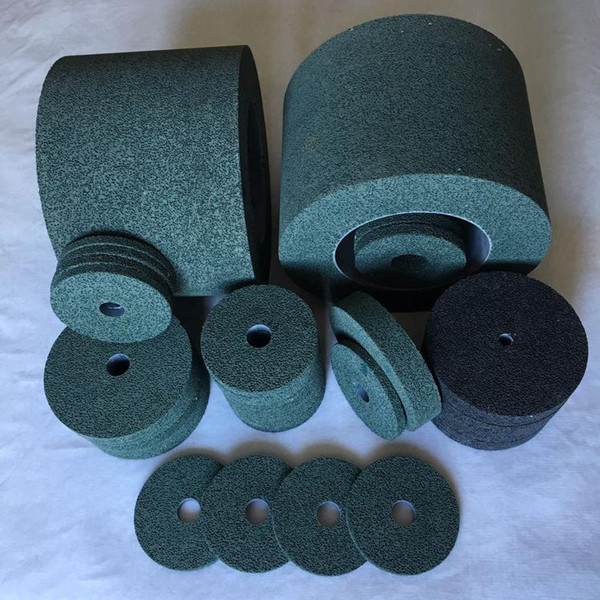

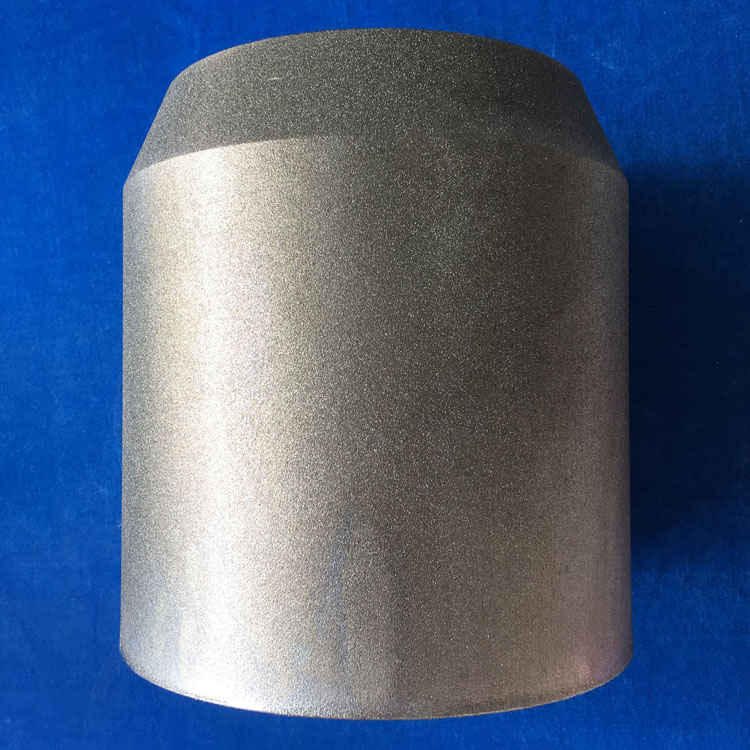

Product detail pictures:

Related Product Guide:

It adheres for the tenet "Honest, industrious, enterprising, innovative" to develop new products and solutions continuously. It regards shoppers, success as its individual success. Let us produce prosperous future hand in hand for Hot sale Factory porcelain diamond blade 300mm - Diamond cutting disc for cutting jade/agate – Kemei , The product will supply to all over the world, such as: Serbia , Cairo , Malta , Products have been exported to Asia, Mid-east,European and Germany market. Our company has constantly been able to update the products performance and safety to meet the markets and strive to be top A on stable quality and sincere service. If you have the honor to do business with our company. we will definitely do our very best to support your business in China.

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.