Hot New Products Steel Cutting Wheel- Black diamond polishing wheel – Kemei

Hot New Products Steel Cutting Wheel- Black diamond polishing wheel – Kemei

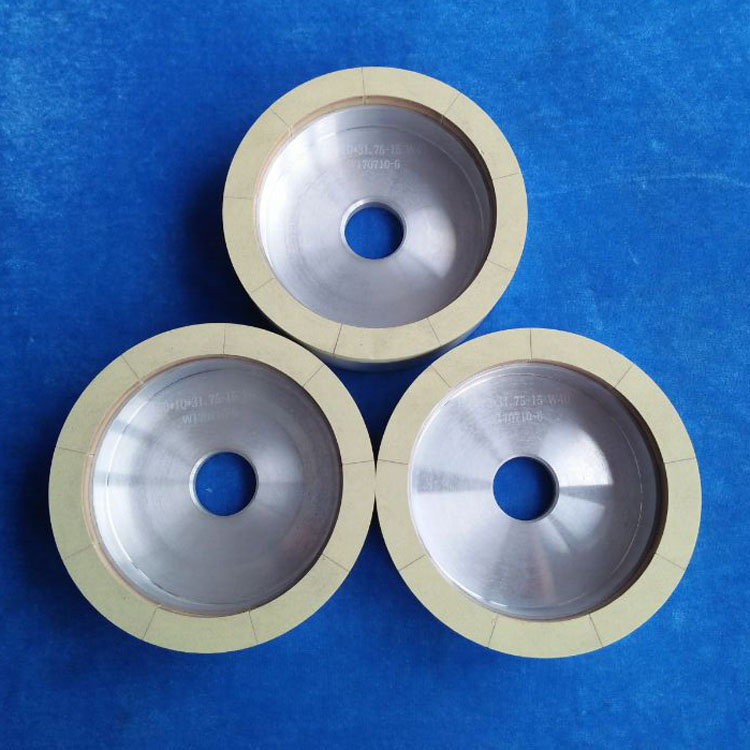

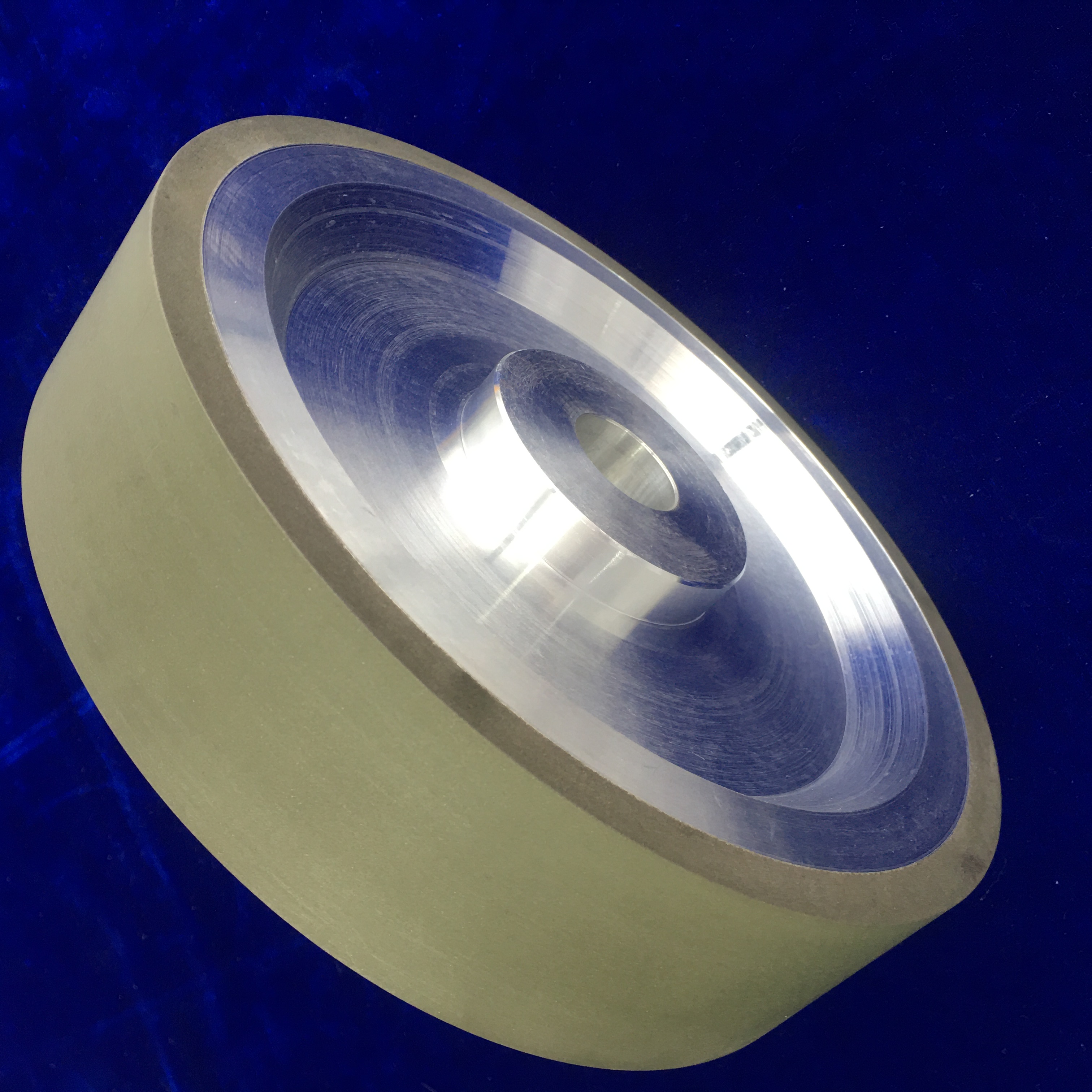

Hot New Products Steel Cutting Wheel- Black diamond polishing wheel – Kemei Detail:

Features: safety, even grinding force, even processing results, wear-resistant, water-resistant, strong plasticity, good softness, suitable for grinding body of various shapes, dirt will not block the grinding surface seam, increase the surface adhesion of the abrasive; control cutting, will not damage the surface of the abrasive; no rust, no falling off, grinding sound is small, dust is small, etc. Black diamond has better grinding effect than common angle grinder and louver wheel.

Scope of application: remove general coating and polished surface, can be used for stainless steel, low carbon steel, aluminum, plastic, cement, wood and stone surface. It is applicable to automobile manufacturing and repair industry, construction industry, chemical light industry, ship manufacturing and repair industry, machinery manufacturing industry, furniture manufacturing, decoration industry, municipal engineering and self repair industry.

Product advantages:

1. Safety: non metallic, not like wire brush.

2. Uniform: due to the uniform distribution of the sulfonated sand on the weaving dimension, when a layer of the surface is worn out, the new ground velvet can play an immediate effect and the processing result is even.

3. Strong water resistance: special fabric material is water and oil resistant.

4. Strong plasticity: good softness, suitable for various shapes of the ground body.

5. Not easy to block: the new pile surface will form naturally after the loss of the ground pile, and the dirt will not block the fine seam, so that the ground surface is always as new as before.

6. Increase adhesion: the abrasive wool can leave ultra-fine traces on the surface of the object, increase the real area of the surface, which is conducive to the adhesion effect of paint spraying, paint baking and so on.

7. Control cutting: do not over cut the abrasives, resulting in defective products.

8. No rust, no falling off: no rust, no falling off, no use like wire brush

9. Safe working environment: noise, dust, mistakes are taboos for safe operation. Industrial use of Bailey grinding, grinding sound small, dust less, to provide users with a comfortable working environment.

Product detail pictures:

Related Product Guide:

As a way to present you with ease and enlarge our enterprise, we also have inspectors in QC Workforce and assure you our greatest support and solution for Hot New Products Steel Cutting Wheel- Black diamond polishing wheel – Kemei , The product will supply to all over the world, such as: Stuttgart , Indonesia , New York , We have been committed to meet all your needs and solve any technical problems you may encounter with your industrial components. Our exceptional products and vast knowledge of technology makes us the preferred choice for our customers.

The product manager is a very hot and professional person, we have a pleasant conversation, and finally we reached a consensus agreement.