Factory Promotional closed coat- Graphite grinding wheel, resin powder, mirror polishing wheel, roller bearing steel – Kemei

Factory Promotional closed coat- Graphite grinding wheel, resin powder, mirror polishing wheel, roller bearing steel – Kemei

Factory Promotional closed coat- Graphite grinding wheel, resin powder, mirror polishing wheel, roller bearing steel – Kemei Detail:

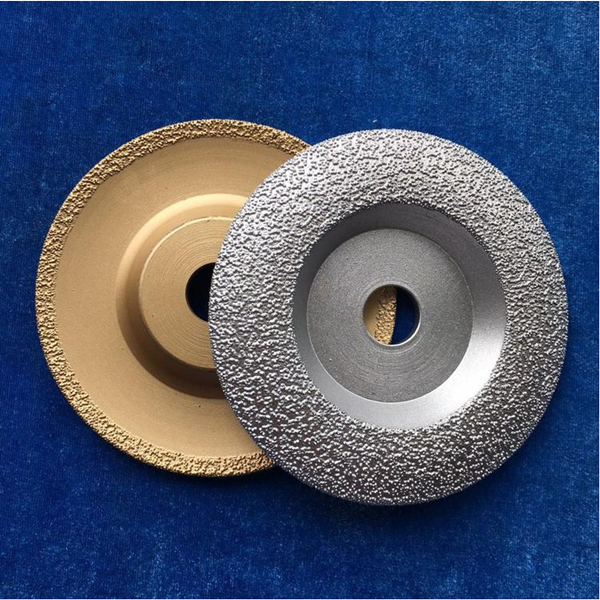

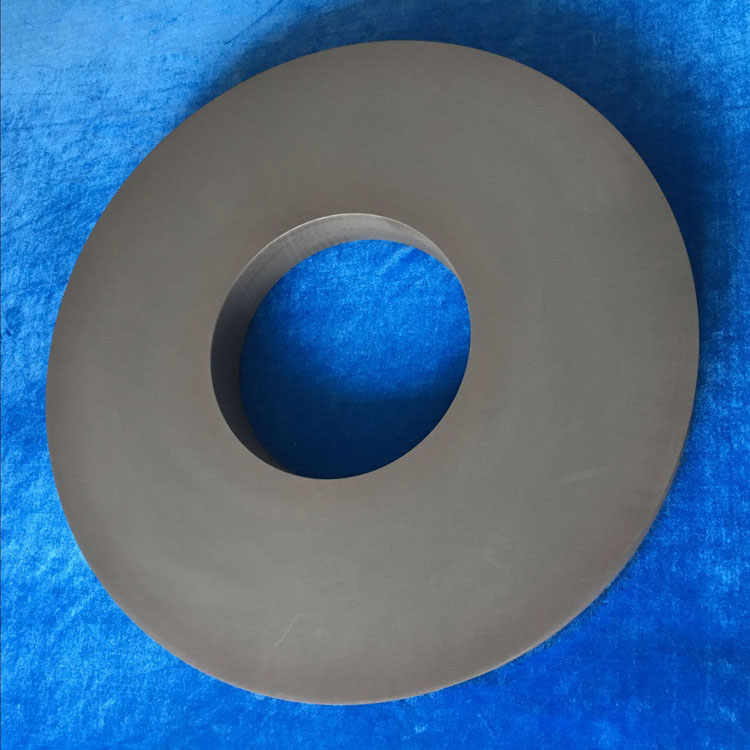

Due to the small expansion coefficient of graphite and its ability to withstand the changes of rapid cooling and heat, it can be used as a mold for glassware. After using graphite, the castings obtained from ferrous metal have accurate size, smooth surface, high yield, and can be used without processing or a little processing, thus saving a lot of metals. In the production of cemented carbide and other powder metallurgy processes, graphite materials are usually used to make the boat dishes for pressing and sintering. Crystal growth of monocrystalline silicon, regional refining vessels, brackets, clamps, induction heaters, etc., are all processed with high-purity graphite. In addition, graphite can also be used as insulation board and base of vacuum smelting graphite, high temperature resistance furnace tube, rod, plate, grid and other components.Graphite grinding wheel is mainly used for ultra precision grinding, polishing and mirror grinding with small grinding allowance. This kind of grinding wheel has good elasticity, high precision and low roughness of the workpiece to achieve mirror effect

It is mainly used for mirror surface polishing and ultra precision grinding, with a surface finish of ra0.01. In addition, it has green silicon carbide micro powder grinding wheel, which is used for fine grinding and ultra precision grinding with a relatively large processing amount. It can be used for external circle polishing, plane polishing, cutting edge grinding of cutters, centerless grinding stone and ink grinding wheel, and micro powder grinding wheel, which can be used for fine grinding and polishing of cylindrical workpieces such as connecting rod, piston rod, piston pin, bearing roller, etc Optical process, welcome to sample orders from major manufacturers.

Product detail pictures:

Related Product Guide:

It adheres on the tenet "Honest, industrious, enterprising, innovative" to develop new items frequently. It regards buyers, success as its very own success. Let us produce prosperous future hand in hand for Factory Promotional closed coat- Graphite grinding wheel, resin powder, mirror polishing wheel, roller bearing steel – Kemei , The product will supply to all over the world, such as: Morocco , Belgium , Australia , Our company has built stable business relationships with many well-known domestic companies as well as oversea customers. With the goal of providing high quality products to customers at low cots, we are committed to improving its capacities in research, development, manufacturing and management. We have honored to receive recognition from our customers. Till now we have passed ISO9001 in 2005 and ISO/TS16949 in 2008. Enterprises of "quality of survival, the credibility of development" for the purpose, sincerely welcome domestic and foreign businessmen to visit to discuss cooperation.

This is a honest and trustworthy company, technology and equipment are very advanced and the prodduct is very adequate, there is no worry in the suppliment.