Factory Promotional closed coat- Graphite grinding wheel, resin powder, mirror polishing wheel, roller bearing steel – Kemei

Factory Promotional closed coat- Graphite grinding wheel, resin powder, mirror polishing wheel, roller bearing steel – Kemei

Factory Promotional closed coat- Graphite grinding wheel, resin powder, mirror polishing wheel, roller bearing steel – Kemei Detail:

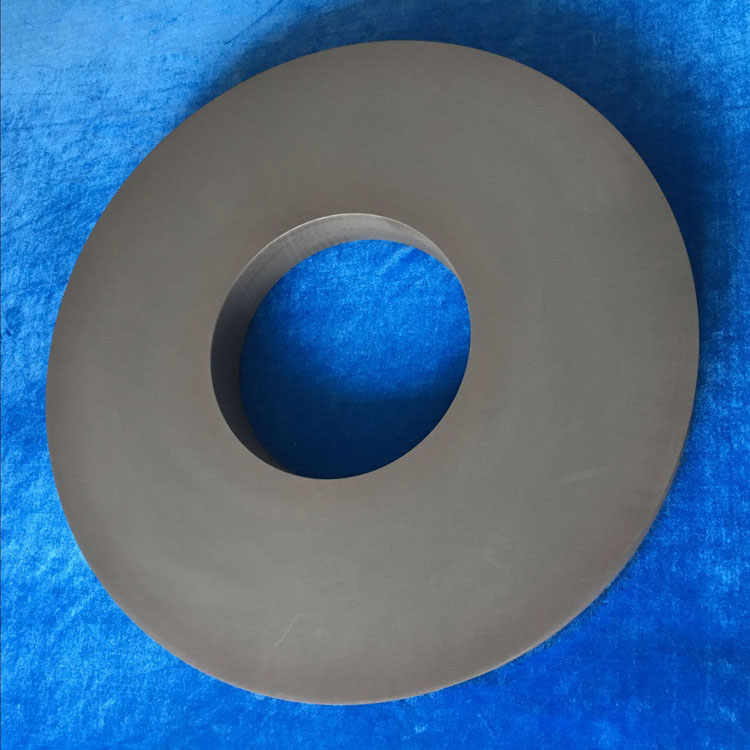

Due to the small expansion coefficient of graphite and its ability to withstand the changes of rapid cooling and heat, it can be used as a mold for glassware. After using graphite, the castings obtained from ferrous metal have accurate size, smooth surface, high yield, and can be used without processing or a little processing, thus saving a lot of metals. In the production of cemented carbide and other powder metallurgy processes, graphite materials are usually used to make the boat dishes for pressing and sintering. Crystal growth of monocrystalline silicon, regional refining vessels, brackets, clamps, induction heaters, etc., are all processed with high-purity graphite. In addition, graphite can also be used as insulation board and base of vacuum smelting graphite, high temperature resistance furnace tube, rod, plate, grid and other components.Graphite grinding wheel is mainly used for ultra precision grinding, polishing and mirror grinding with small grinding allowance. This kind of grinding wheel has good elasticity, high precision and low roughness of the workpiece to achieve mirror effect

It is mainly used for mirror surface polishing and ultra precision grinding, with a surface finish of ra0.01. In addition, it has green silicon carbide micro powder grinding wheel, which is used for fine grinding and ultra precision grinding with a relatively large processing amount. It can be used for external circle polishing, plane polishing, cutting edge grinding of cutters, centerless grinding stone and ink grinding wheel, and micro powder grinding wheel, which can be used for fine grinding and polishing of cylindrical workpieces such as connecting rod, piston rod, piston pin, bearing roller, etc Optical process, welcome to sample orders from major manufacturers.

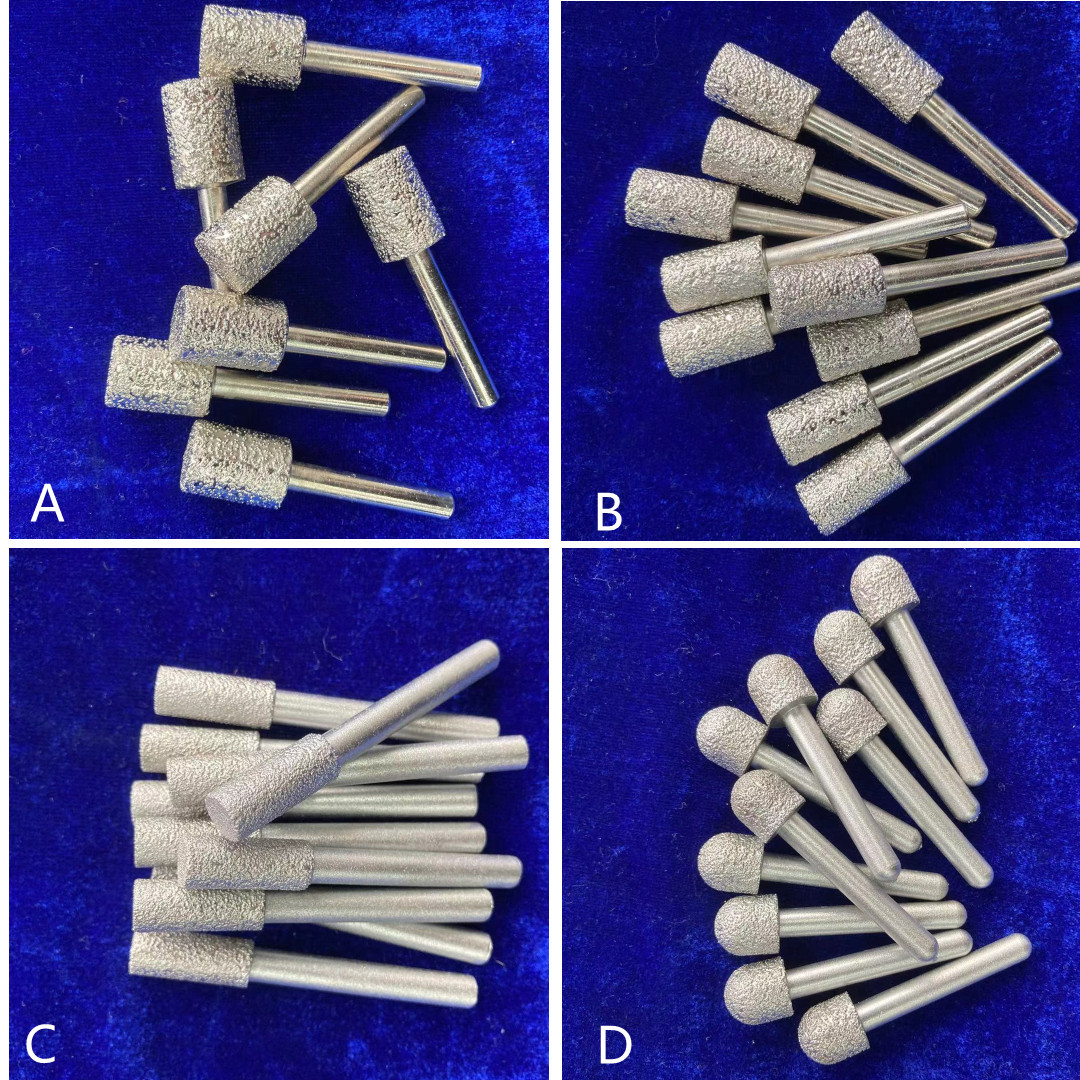

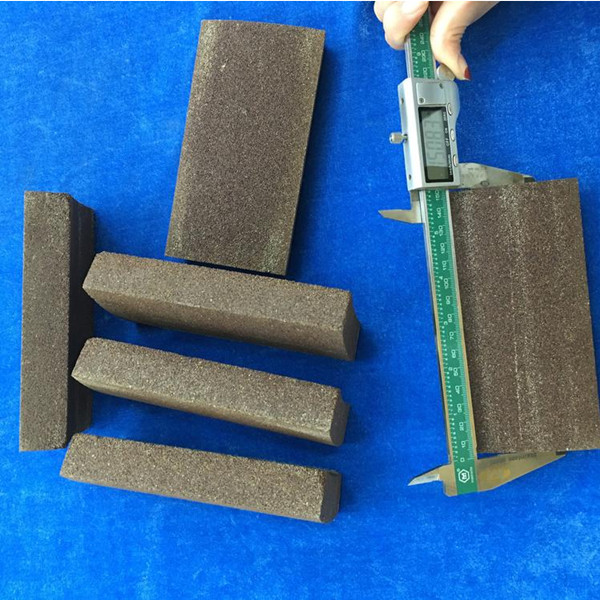

Product detail pictures:

Related Product Guide:

Our company insists all along the quality policy of "product quality is base of enterprise survival; customer satisfaction is the staring point and ending of an enterprise; persistent improvement is eternal pursuit of staff" and the consistent purpose of "reputation first, customer first" for Factory Promotional closed coat- Graphite grinding wheel, resin powder, mirror polishing wheel, roller bearing steel – Kemei , The product will supply to all over the world, such as: New Delhi , Brunei , Mongolia , Our products are exported worldwide. Our customers are always satisfied with our reliable quality, customer-oriented services and competitive prices. Our mission is "to continue to earn your loyalty by dedicating our efforts to the constant improvement of our products and services in order to ensure the satisfaction of our end-users, customers, employees, suppliers and the worldwide communities in which we cooperate".

The product manager is a very hot and professional person, we have a pleasant conversation, and finally we reached a consensus agreement.