Factory making total porosity- Resin diamond cup wheel – Kemei

Factory making total porosity- Resin diamond cup wheel – Kemei

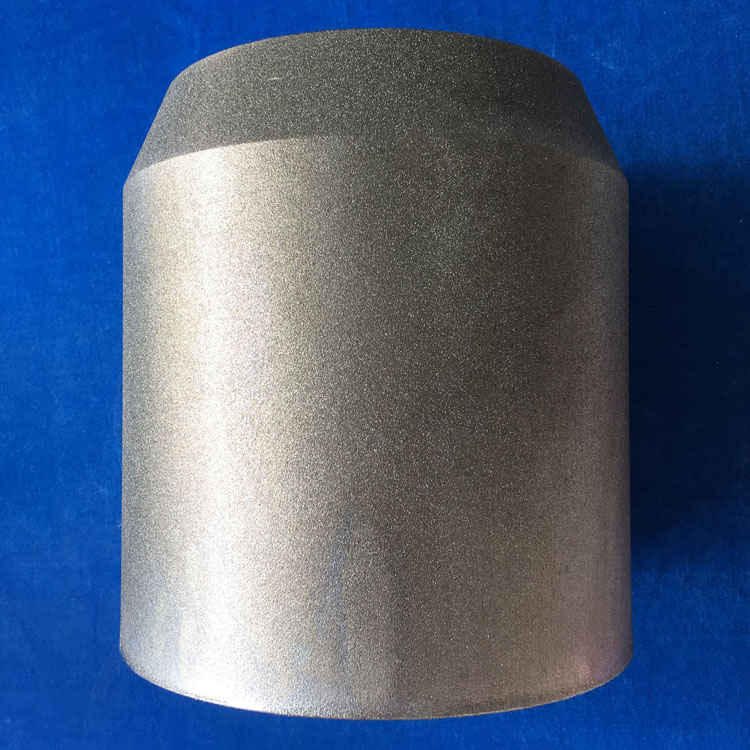

Factory making total porosity- Resin diamond cup wheel – Kemei Detail:

Diamond resin grinding wheel has high hardness, high strength and strong grinding ability. It is mainly used for grinding high and hard alloy, non-metallic material, cutting hard and brittle hard alloy, non-metallic mineral, etc. Such as hard alloy, ceramics, agate, optical glass, semiconductor materials and wear-resistant cast iron, stone and so on.

Diamond resin grinding wheel has a good polishing effect. When grinding, the grinding wheel is sharp and not easy to block.

The specific characteristics are as follows:

1. High grinding efficiency and relatively slow consumption of grinding wheel;

2. It has good self sharpening property, small heat generation during grinding, and is not easy to block, which reduces the phenomenon of work burn during grinding;

3. The grinding wheel has certain elasticity, which is conducive to improving the surface roughness of the workpiece. It is mainly used in fine grinding, semi-fine grinding, knife grinding, polishing and other processes;

4.The diamond resin grinding wheel is solidified at low temperature, with short production cycle, simple equipment and supply process; because of the fluidity of resin, it is easy to form complex grinding wheel.

It is mainly used for grooving and cutting of various non-metallic materials, including:

1) , semiconductors and their packaging materials

2) Ceramic materials

3) . magnetic materials

4)Other materials: crystal, glass, quartz, gem, hard alloy, printed circuit board, etc.

What information should be provided when ordering?

A: due to the complexity of diamond tool specifications and the strong specificity of some varieties, in order to minimize the errors caused by users when ordering, the company will try its best to provide users with good services, and also ask users to cooperate closely to avoid mistakes. Now the ordering instructions are introduced as follows:

When ordering products, please tell us the following information as much as possible: the model, size (outer diameter, thickness, aperture, width and depth of abrasive layer), abrasive type, particle size, binder type, concentration, grinding method (dry or wet grinding) and processed materials, etc.

Product detail pictures:

Related Product Guide:

Our personnel are always in the spirit of "continuous improvement and excellence", and with the superior quality products, favorable price and good after-sales services, we try to win every customer's trust for Factory making total porosity- Resin diamond cup wheel – Kemei , The product will supply to all over the world, such as: Ukraine , Lahore , Norwegian , When It produced, it making use of the world's major method for reliable operation, a low failure price, it appropriate for Jeddah shoppers choice. Our enterprise. s situated inside the national civilized cities, the website traffic is very hassle-free, unique geographical and financial circumstances. We pursue a "people-oriented, meticulous manufacturing, brainstorm, make brilliant" company philosophy. Strict good quality management, fantastic service, affordable cost in Jeddah is our stand around the premise of competitors. If needed, welcome to make contact with us by our web page or phone consultation, we'll be delighted to serve you.

The customer service staff is very patient and has a positive and progressive attitude to our interest, so that we can have a comprehensive understanding of the product and finally we reached an agreement, thanks!