Factory Directly supply structure- Resin diamond CBN grinding disc double face grinding wheel – Kemei

Factory Directly supply structure- Resin diamond CBN grinding disc double face grinding wheel – Kemei

Factory Directly supply structure- Resin diamond CBN grinding disc double face grinding wheel – Kemei Detail:

CBN grinding wheel for steel grinding

Artificial synthesis production: covalently connected cubic boron nitride, CBN is the second hard material, and the hardness is about hv4500. CBN has high thermal conductivity and chemical stability, which makes it suitable to process steel materials and obtain high cutting performance in grinding process. In order to give full play to the potential of CBN, using high cutting speed is the basic requirement of CBN wheel. Many kinds of CBN lead us to provide different applications according to the situation of grinding wheel. Steel, nickel base alloy or high speed steel: CBN is always the right grinding material you can choose.

*High speed steel shrinkage written as HS meets the new standard (EN ISO 4957)CBN or diamond

Abrasive is the best choice for large cutting and high cutting speed. It can be used for rough and finish machining. High efficiency can be obtained without dressing.

Forming roller with single axial feed

Single axial feed forming rollers are usually used for dressing many different kinds of grinding wheels for mass production. Shorter dressing time and longer tool life lead to high efficiency of production and consistency of technology. All kinds of common grinding wheels and special superhard grinding wheels can be dressed by this method. CD dressing (continuous dressing) is often used for dressing hardened workpieces and precision formed grinding wheels of super heat-resistant stainless steel. For various dressing applications, Dr. Kaiser can provide dressing tools for specific applications to achieve the required tolerance and tool life.

It is used in many applications: screw, blade, support journal, bearing channel, valve, engine valve, fuel injection component.

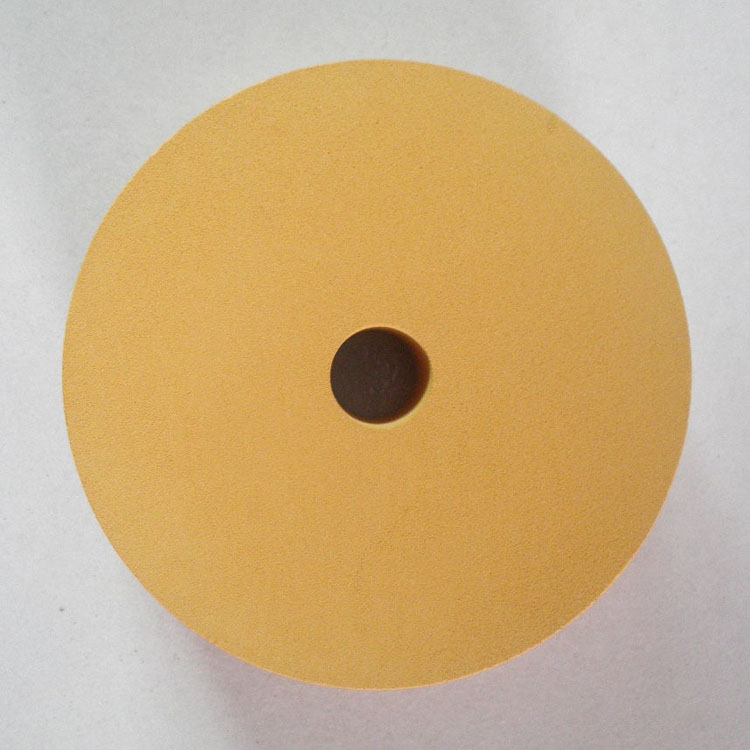

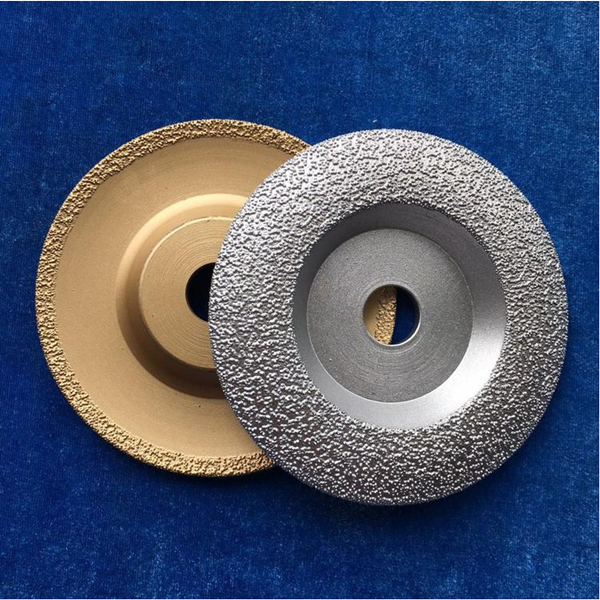

Product detail pictures:

Related Product Guide:

Our enterprise insists all along the standard policy of "product high-quality is base of business survival; client satisfaction could be the staring point and ending of an business; persistent improvement is eternal pursuit of staff" as well as consistent purpose of "reputation first, client first" for Factory Directly supply structure- Resin diamond CBN grinding disc double face grinding wheel – Kemei , The product will supply to all over the world, such as: Cannes , Lesotho , Maldives , Really should any of these items be of interest to you, please let us know. We will be pleased to give you a quotation upon receipt of one's detailed specifications. We've our personal specialist R&D enginners to meet any of the requriements, We look forward to receiving your enquires soon and hope to have the chance to work together with you inside the future. Welcome to take a look at our organization.

The company keeps to the operation concept "scientific management, high quality and efficiency primacy, customer supreme", we have always maintained business cooperation. Work with you,we feel easy!