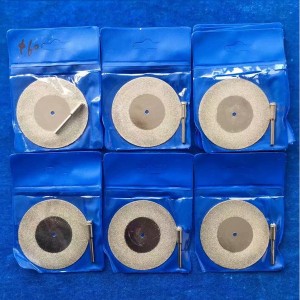

Diamond cutting disc/Jade cut-off disc/Glass cutting disc/Tooth grinding disc/Diamond small grinding wheel

Diamond cutting disc/Jade cut-off disc/Glass cutting disc/Tooth grinding disc/Diamond small grinding wheel

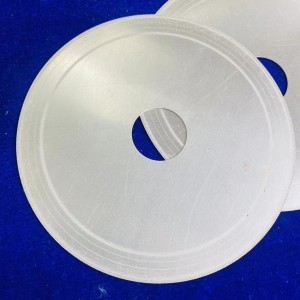

Electroplated metal has the control force to diamond, not only has the mechanical meshing effect,also has the intermolecular forces.

Electroplated diamond cutting disc is made of diamond as abrasive by electrodeposition of metal.

Advantages of electroplated diamond cutting discs:

1. Good diamond control force, not easy to fall off prematurely, so that the diamond can be fully used;

2. Suitable for manufacturing thin thickness discs, suitable for fine cutting;

3. It has little influence on the matrix performance, has no thermal damage to diamond, maintains the original strength of diamond, and gives full play to the characteristics of diamond;

4. The production process of electroplated diamond cutting disc is simple, the cycle is small, the cost is low, and the mass production is fast and efficient.

Features of the small diamond grinding cutting disc:

- Small kerf

- High sharpness

- Fast cutting&grinding

- Dry and wet use

Applied to:The small diamond cutting disc is widely used for the jade,glass and tooth grinding and cutting.

Our company, as the leader of precision and ultra precision grinding tools, combines foreign honing technology, advanced technology and high-end equipment in Europe and America, and cooperates with domestic well-known grinding tool research and development institutions. Its high-precision diamond reamer and diamond roller are widely used in the fields of automobile, hydraulic pressure, bearing, machine tool, aerospace and military industry.