Cheapest Factory dulling- Grinding head of sintered diamond ring wheel – Kemei

Cheapest Factory dulling- Grinding head of sintered diamond ring wheel – Kemei

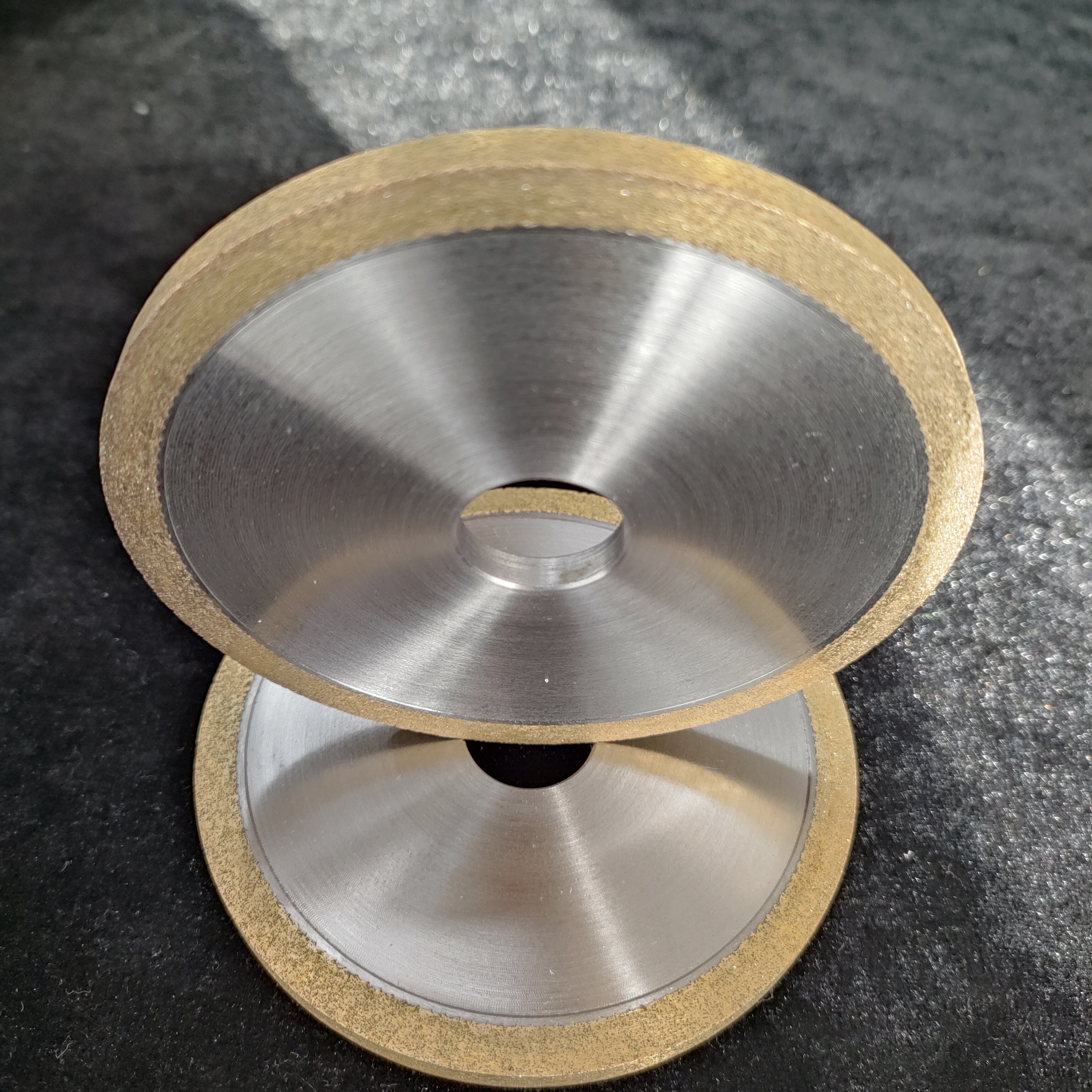

Cheapest Factory dulling- Grinding head of sintered diamond ring wheel – Kemei Detail:

1、 Structure of electroplated diamond and CBN products

(1) The overall structure of electroplating products of superhard materials generally includes three parts: working layer, transition layer and substrate, while the structural feature of electroplating products is that there is no over coating, which is generally composed of two parts: electroplated layer and substrate layer.

(2) Working layer (electroplated layer)

It is composed of superhard material and electroplated metal bond. The particles of superhard material are consolidated in the metal coating in dispersion state. It is the working part and plays the role of grinding.

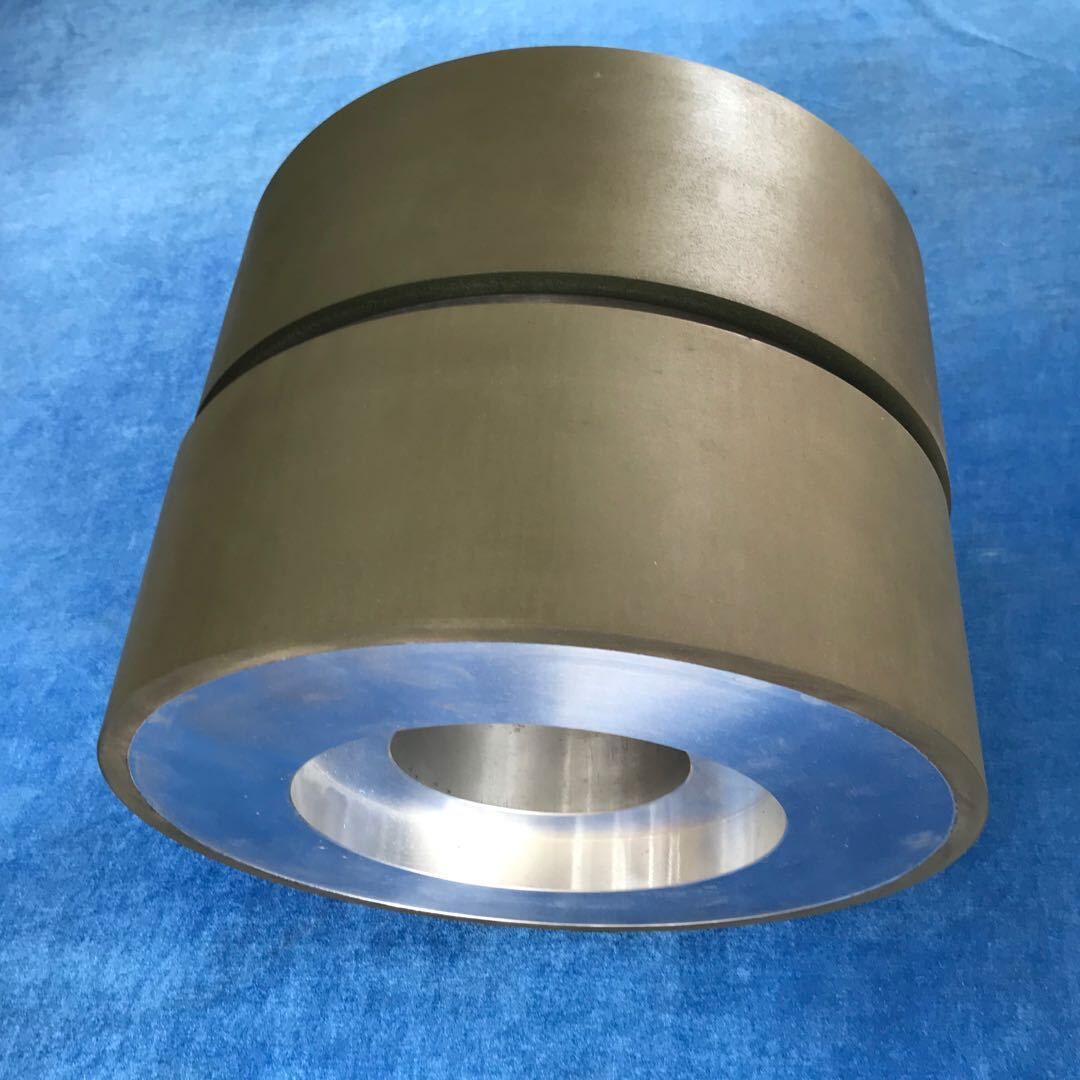

(3) Matrix

Generally, it is made of steel by machining, which requires a certain direction, shape, dimensional accuracy and surface finish. The shape of electroplated products depends on the shape of the substrate. It supports the electroplated layer and is easy to install and use.

2、 Shape characteristics

The other characteristic of electroplating products of superhard materials is the special shape. The electroplating method can be used to manufacture all kinds of tools with special profile, or very thin, very small, and high geometric and dimensional accuracy requirements. These tools are often used for high-precision machining of special shape parts. The working layer of electroplated products is generally thin, which is another feature of its structure.

3、 Characteristics of electroplating superhard products

(1) Concentration

The concentration of abrasives in electroplating products of superhard materials is very high, generally at 200%. The volume ratio of abrasives is about 50%, even higher, up to 65%.

(2)Binding force

Among all kinds of superhard products, the working layer of electroplated products has the most tight metal bond, the most sufficient contact, the most solid consolidation and the most controlling force. It is because of the strong binding force that the electroplating products are allowed to use high concentration without premature falling off.

(3)Porosity

The porosity of electroplated products is considered to be almost zero.

(4) High hardness

The electroplating products of superhard materials are usually electroplated with nickel or nickel cobalt alloy as binder. This kind of metal bond has a high hardness (HRC = 40). In addition, the structure is compact and the bonding force is strong, which makes the overall hardness of the working layer significantly higher than other abrasives.

4、 Characteristics of molding performance

Because electrodeposition is the continuous growth of metal ions next to the substrate surface, and under the appropriate electroplating process conditions, it can ensure good uniform plating ability and deep plating ability, so that the distribution of metal coating on the substrate surface is complete, and the sole plate degree is even, so what shape is the substrate to be plated, and what shape the formed coating can maintain. For all kinds of complex shape and special surface products, problems that cannot be solved by other forming methods can be easily solved by electroplating forming method. Excellent forming performance is one of the most significant characteristics of electroplating process.

5、 Use properties

The superhard abrasives in the working layer of electroplated products are generally single-layer. For single-layer electroplated products, the abrasive exposed about 1 / 3 of its diameter, so the cutting is sharp, easy to remove chips, small friction and less heat. The characteristics of electroplated products are high machining efficiency, high grinding ratio, good shape retention and high machining accuracy

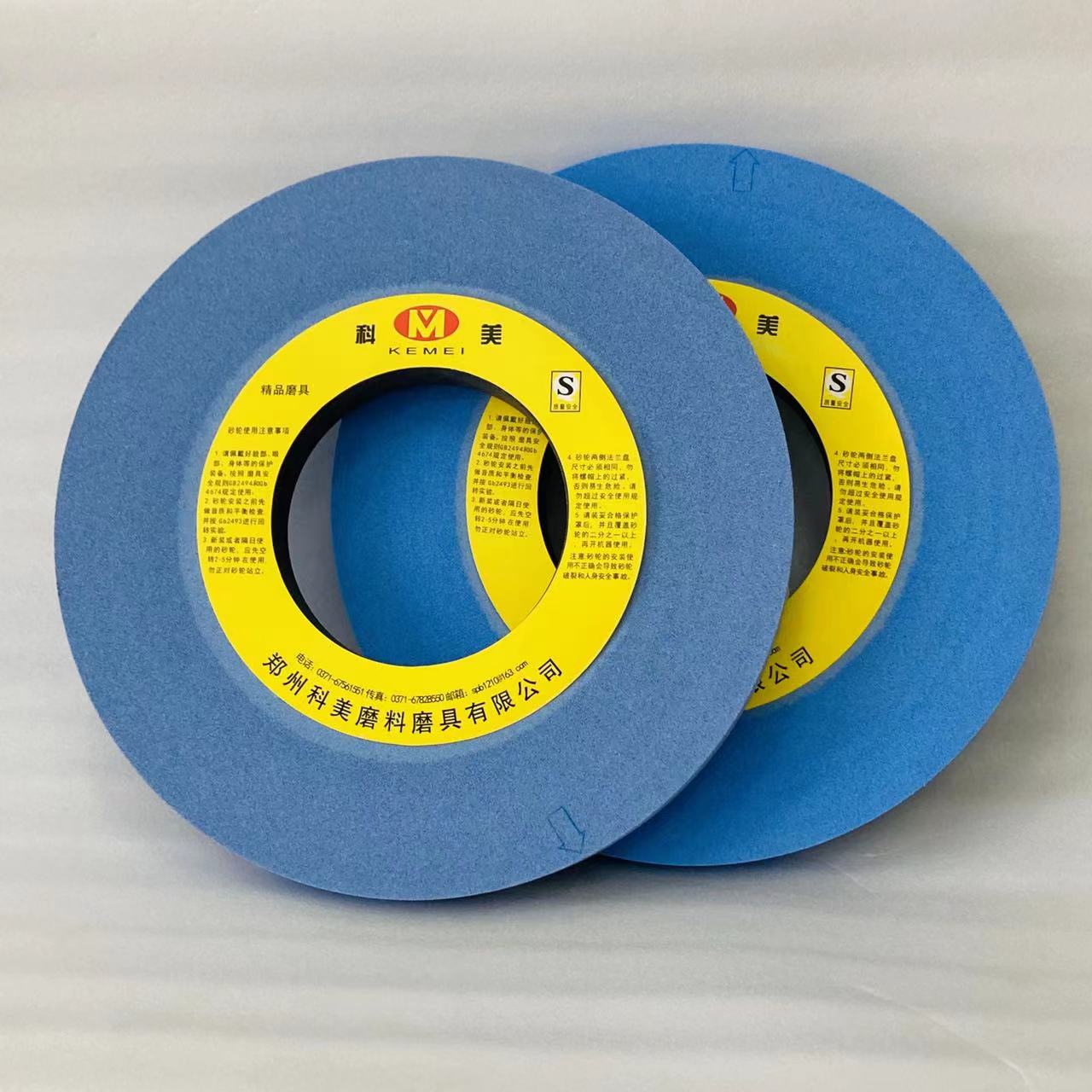

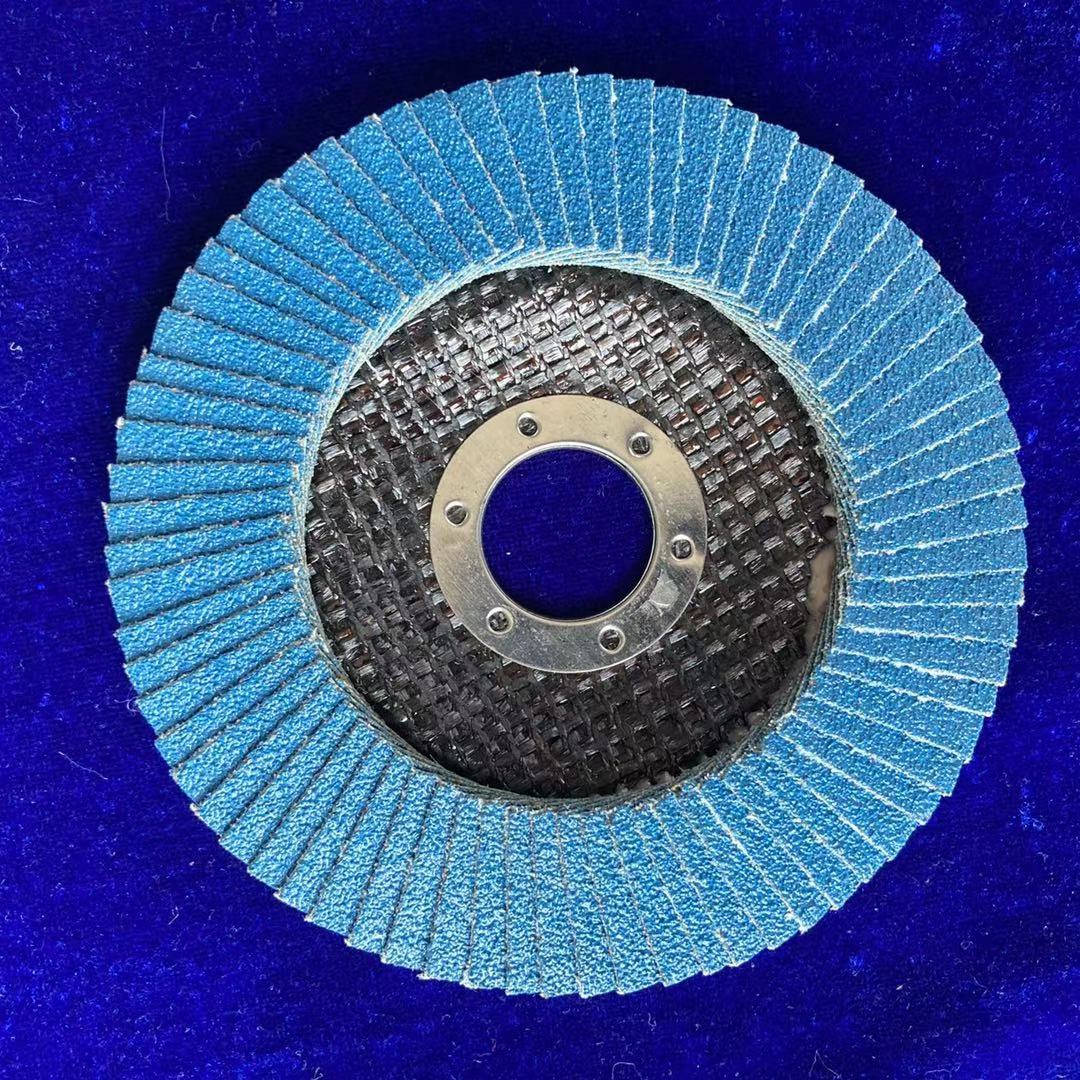

Product detail pictures:

Related Product Guide:

The shopper satisfaction is our primary focus on. We uphold a consistent level of professionalism, quality, credibility and repair for Cheapest Factory dulling- Grinding head of sintered diamond ring wheel – Kemei , The product will supply to all over the world, such as: Armenia , Jersey , Croatia , As a way to use the resource on the expanding info in international trade, we welcome prospects from everywhere on the web and offline. In spite on the high quality objects we offer you, effective and satisfying consultation service is supplied by our qualified after-sale service group. Item lists and in depth parameters and any other info weil be sent to you timely for the inquiries. So you should make contact with us by sending us emails or call us when you've got any questions about our organization. ou could also get our address information from our site and come to our enterprise. We get a field survey of our merchandise. We're confident that we are going to share mutual accomplishment and create solid co-operation relations with our companions within this market place. We're seeking forward for your inquiries.

Good quality and fast delivery, it's very nice. Some products have a little bit problem, but the supplier replaced timely, overall, we are satisfied.