Cheap price Electroplated grinding wheel- Resin ultra thin cutting blade – Kemei

Cheap price Electroplated grinding wheel- Resin ultra thin cutting blade – Kemei

Cheap price Electroplated grinding wheel- Resin ultra thin cutting blade – Kemei Detail:

Superhard abrasive has high hardness, so it can process all kinds of materials with high hardness, especially those difficult to be processed by ordinary abrasive. For example, using diamond grinding tools to process cemented carbide, non-metallic materials such as ceramics, agate, optical glass, semiconductor materials, stone materials, concrete and non-ferrous metals, etc.; using CBN grinding tools to process tool steel, mold steel, stainless steel, heat-resistant alloy, etc., especially processing high vanadium high-speed steel and other ferrous metals, can obtain satisfactory processing results. The grinding temperature of the superhard cutting piece is low, which can greatly improve the surface quality of the workpiece to be processed and avoid the defects such as cracks, burns, structural changes and so on.

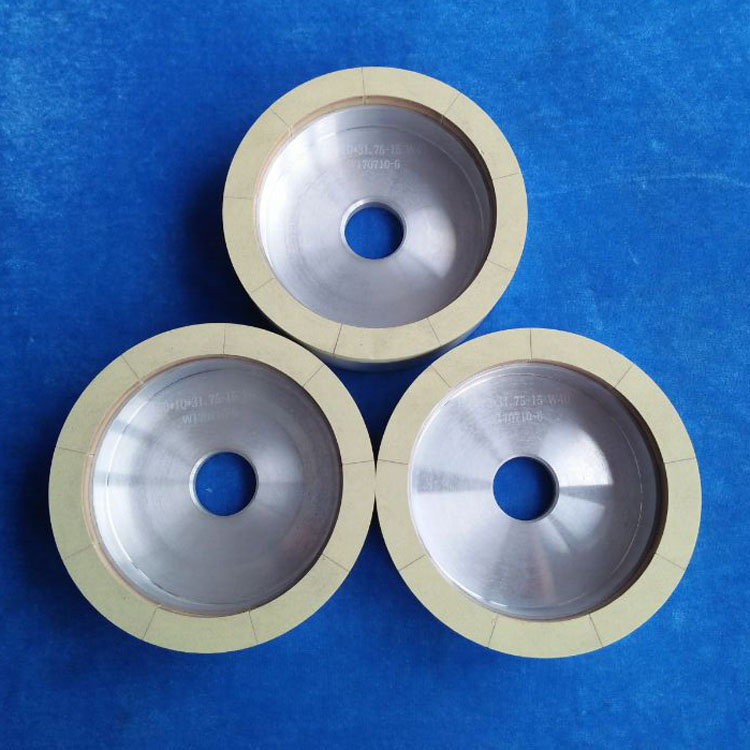

Resin cutting piece

Features: the ultra-thin resin cutting sheet is made of resin as binder, combined with a variety of materials, especially for alloy steel, stainless steel and other difficult cutting materials. Dry and wet cutting methods make the cutting accuracy more stable. At the same time, the choice of material and hardness of the cutting pieces can greatly improve your cutting efficiency and save your production cost.

Material: white corundum, brown corundum, chrome corundum, single crystal corundum, aluminum silicon carbide, black silicon carbide

Application: it is used for cutting stainless steel pipe, capillary, glass pipe, quartz pipe, automobile exhaust pipe, brake line, tungsten wire, molybdenum wire, copper wire and other pipe fittings and filaments. It has good effect on cutting special steel and slotting workpiece.

Our philosophy:

·Adhering to the concept of “user first”, creating value for users and maintaining users’ legitimate interests are the first priority of operation;

·Keep sensitive to users’ needs, pay attention to users’ consumption experience, and appropriately exceed users’ expectations in service level;

·Pay attention to cultivate the satisfaction and loyalty of users, and constantly improve the service level of communication with users;

·To maximize the user value to create the maximum value of the company.

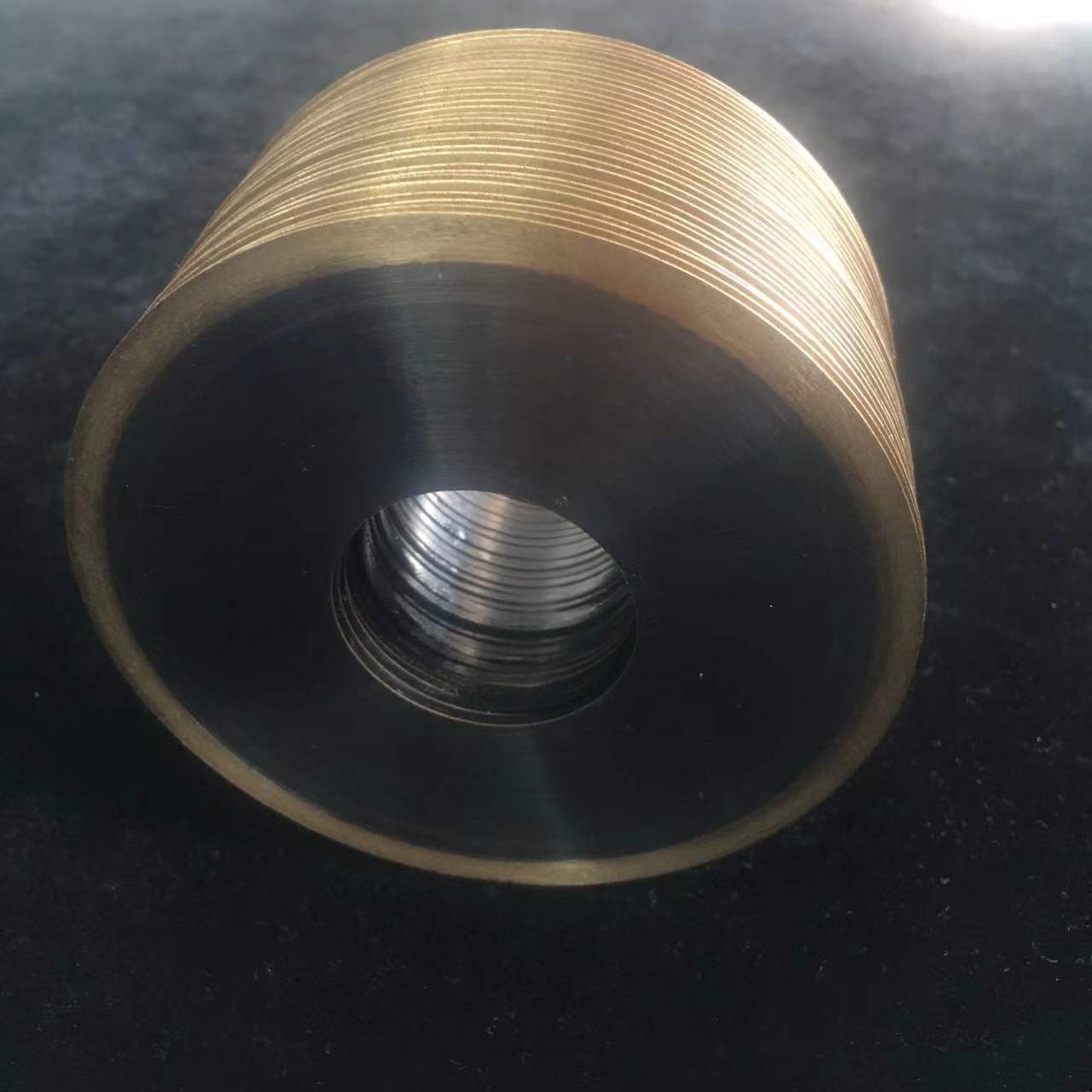

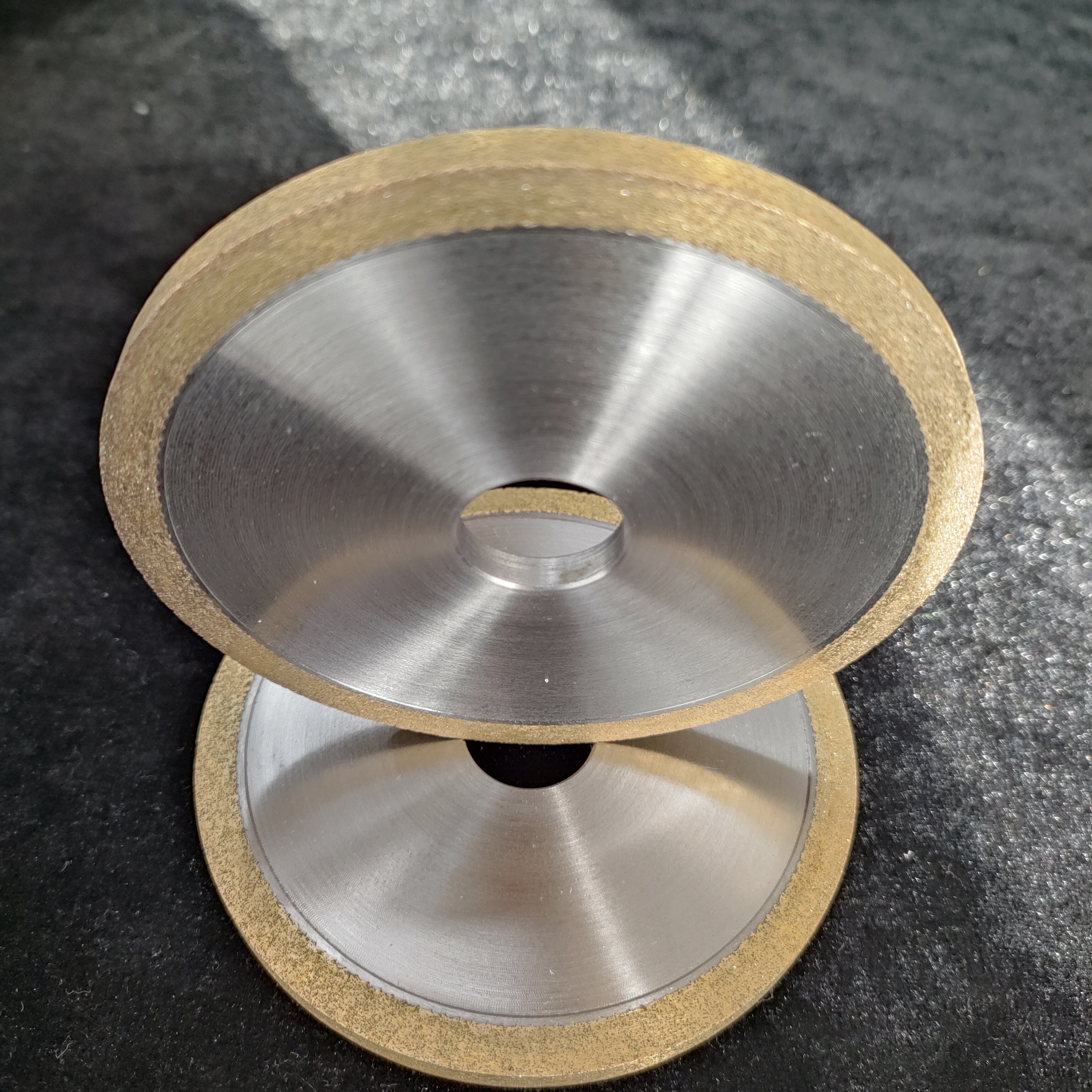

Product detail pictures:

Related Product Guide:

We've got a really efficient group to deal with inquiries from prospects. Our purpose is "100% customer fulfillment by our product excellent, price & our group service" and enjoy a superb track record amid clientele. With many factories, we can easily deliver a wide selection of Cheap price Electroplated grinding wheel- Resin ultra thin cutting blade – Kemei , The product will supply to all over the world, such as: Macedonia , Russia , Poland , Abiding by our motto of "Hold well the quality and services, Customers Satisfaction", So we give our clients with high quality products and solutions and excellent service. Be sure to feel free to contact us for further information.

The factory has advanced equipment, experienced staffs and good management level, so product quality had assurance, this cooperation is very relaxed and happy!