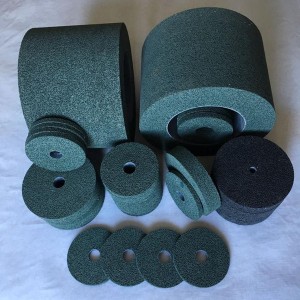

Ceramic black silicon carbide air hole grinding wheel

Ceramic black silicon carbide air hole grinding wheel

Application of black silicon carbide in consolidation abrasives

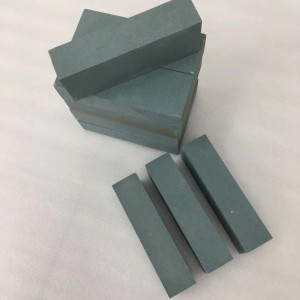

Black silicon carbide is produced in electric high temperature resistance furnace with quartz sand and petroleum coke as the main raw material. Its hardness is between corundum and synthetic diamond. The mechanical strength is higher than that of corundum.

standard

2. Proportion of magnetic material: ≤ 0.0300%.

application program

Black silicon carbide + 30 is mainly used for abrasive grinding products, resin grinding wheel, PVA grinding wheel, etc.

features

1. All products have strong stability, good resistance and oxidation resistance.

2. All products are of high quality and purity in strict accordance with national test standards.

3. Adjust the shape of abrasive particles according to the working environment of customers, greatly improving the applicability of products, more economical and practical.

4. Products can be customized according to customers' needs.

packing

1. PP bag or paper bag tray, ton bag.

2. The package can be customized.

1. We have passed the ISO9001:2000 certification.

2. Our company has two laboratories for chemical testing and physical testing, with 15 technicians.

3. All products must pass strict multiple inspection to ensure the quality of products.

4. We keep samples of each batch of products. Many test reports and test reports of each sample will be delivered after 10 months.

advantage

1. With a professional team, we can produce all kinds of products with different particle sizes according to customers' requirements and ensure product standards.

2. We have strict quality inspection system to ensure the quality and safety of products.

3. We also have a perfect after-sales service system.