Best Price for substrate- Resin diamond CBN grinding disc double face grinding wheel – Kemei

Best Price for substrate- Resin diamond CBN grinding disc double face grinding wheel – Kemei

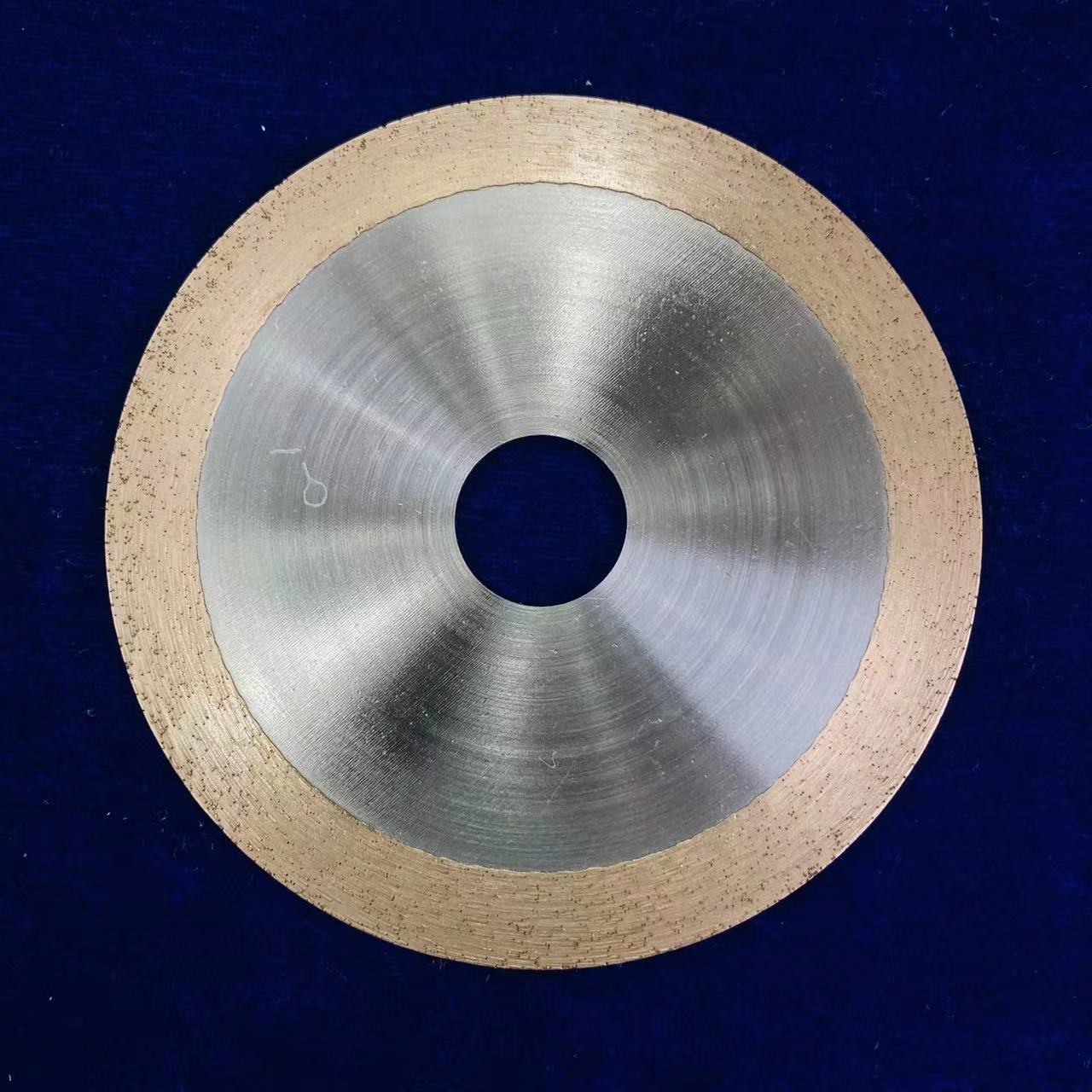

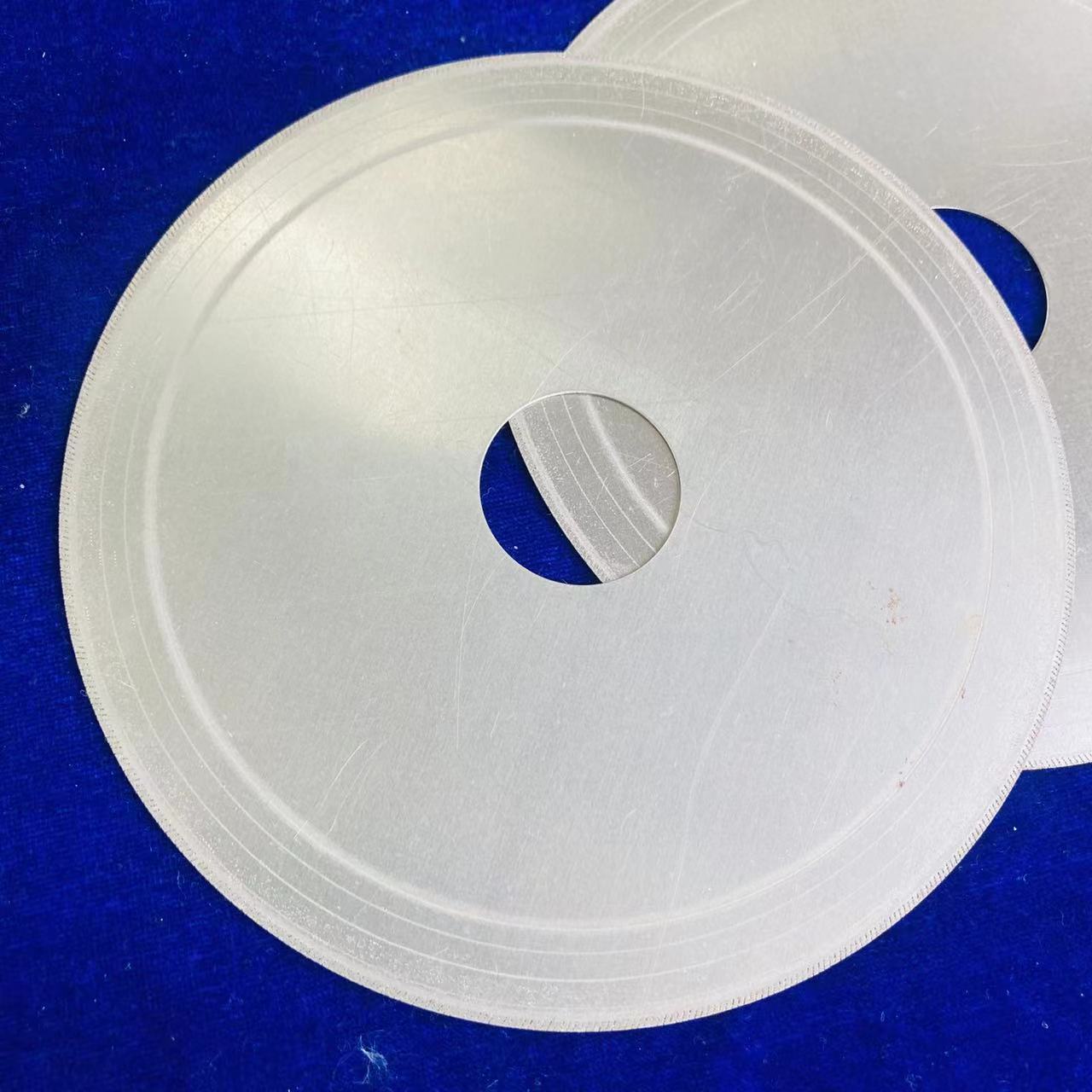

Best Price for substrate- Resin diamond CBN grinding disc double face grinding wheel – Kemei Detail:

CBN (cubic boron nitride) abrasives are made of metal powder, resin powder, ceramic and electroplated metal. The tools used for grinding, polishing and grinding are CBN. CBN (cubic boron nitride) abrasives are composed of three parts: working layer, matrix and transition layer. The working layer, also known as CBN layer, is composed of abrasives, binders and fillers, which is the working part of abrasives. The transition layer, also known as non CBN layer, is composed of binder, metal powder and filler. It is the part that connects CBN layer firmly to the substrate. The base is made of aluminum, steel or bakelite, which plays the role of supporting the working layer and mounting the grinding tool. CBN (cubic boron nitride) Abrasives use: CBN abrasives made of grinding wheel, according to different processing technology and different components of the binder can be divided into the following four.

Their nature and use (referring to machining use) are also different.

(1) The forming process of electroplated CBN grinding wheel is simple and the production cost is low. Forming is simple but only one layer of coating, which can not be corrected. In the process of processing, it is difficult to know when the grinding layer is damaged. It is suitable for small batch machining and complex geometric shape grinding and used as trimming roller.

(2) The sintered CBN grinding wheel has high hardness and density, and it can be processed into high precision dressing roller with high cost. It is mainly used for grinding wheel dressing roller and processing of a large number of superhard materials.

(3) The production process of resin CBN grinding wheel is simple and the production cost is low. Shaping is simple but not easy to correct. It is used for multi shape and small batch processing. Such as tool grinding and tool processing, and glass processing.

(4) CBN grinding wheel with ceramic bond CBN grinding wheel is the most ideal grinding tool with high speed, high efficiency and high precision, which has the advantages of strong force, high speed processing without burning workpiece, revisable and durable. CBN grinding wheel is suitable for processing products of the following materials: high manganese steel; high chromium, nickel, molybdenum alloy steel; chilled cast iron (hs8090); all kinds of hardened steel (hrc5565); all kinds of cast iron (hb200400), etc., and has been processed in domestic automobile (gear, flywheel, shaft, bearing, etc.), roll, slurry pump (impeller, volute, guard plate, sheath, etc.), mould , cylinder liner, glass, gemstone and other high hardness soft and tough materials can solve the cutting of high hardness and difficult to process materials in all walks of life, improve the working efficiency, greatly save the processing time and power, and obtain huge economic benefits.

Product detail pictures:

Related Product Guide:

We support our buyers with ideal high quality products and high level service. Becoming the specialist manufacturer in this sector, we have gained rich practical experience in producing and managing for Best Price for substrate- Resin diamond CBN grinding disc double face grinding wheel – Kemei , The product will supply to all over the world, such as: Jakarta , Croatia , Algeria , Our products and solutions are sold to the Middle East, Southeast Asia, Africa, Europe, America and other regions, and are favorably appraised by clients. To benefit from our strong OEM/ODM capabilities and considerate services, be sure to contact us today. We will sincerely create and share success with all clients.

Timely delivery, strict implementation of the contract provisions of the goods, encountered special circumstances, but also actively cooperate, a trustworthy company!