2020 Latest Design grinding wheel- Small round grinding wheel with handle grinding head – Kemei

2020 Latest Design grinding wheel- Small round grinding wheel with handle grinding head – Kemei

2020 Latest Design grinding wheel- Small round grinding wheel with handle grinding head – Kemei Detail:

Sharp edges for efficient cutting High-precision processing for consistent qualityHigh hardness for long life

A variety of shapes are available in an abrasive grain to suit the desired material to be ground.

Cutting grindstones, offset, flexible grinding stones, segmented, internal grinding,

cylindrical grinding, surface grinding, centerless, axis-based grinding wheels and more.

Abrasive grains: GC, C, WA, A, SSG and more

Diamond grinding wheels and CBN grinding wheels are used for grinding metals with a high hardness.

These grinding wheels have a low wear and an extremely high grinding ability.

Low hardness dropout makes them optimal for grinding a large number of products to specific measurements.

High cutting ability of the material means you can plan to spend less time grinding.

Diamond grinding wheels can grind non-ferrous metals and CBN grinding wheels can grind ferrous materials.

We can also make flat blades to your specifications. In addition,

we can help you select from a wide variety of materials depending on the usage of your blade.

We can make not only smaller blades but also longer blades over 1000 mm in length.

Main uses: paper, non-woven fabric (diapers, sanitary napkins, etc.), film, packaging machines

Feature

1. High heat resistance

2. High grinding efficiency, can grinding & polishing quickly.

3. No-dust ollution, safe & reliable.

4. Long service life.

5. Easy to use, greatly save manual labor, and save production cost.

6. Can process metal or non-metal parts and various artwork. Choose different shape according to the machined parts.

Application range

Industry: mold parts, mechanical parts, etc

Artwork:wood carving, stone carving, jsde carving, ceramic artwork,etc

Automotive industry:cykinder processing, rounded corner of oil hole of crankshaft,etc

Optical processing industry: high precision grinding for glasses frame,etc

Electrical engineering|: super finishing for the burr of small parts,etc

Gemstone processing industry:super finishing for precious metal parts,etc

super finishing for dental equipment,etc

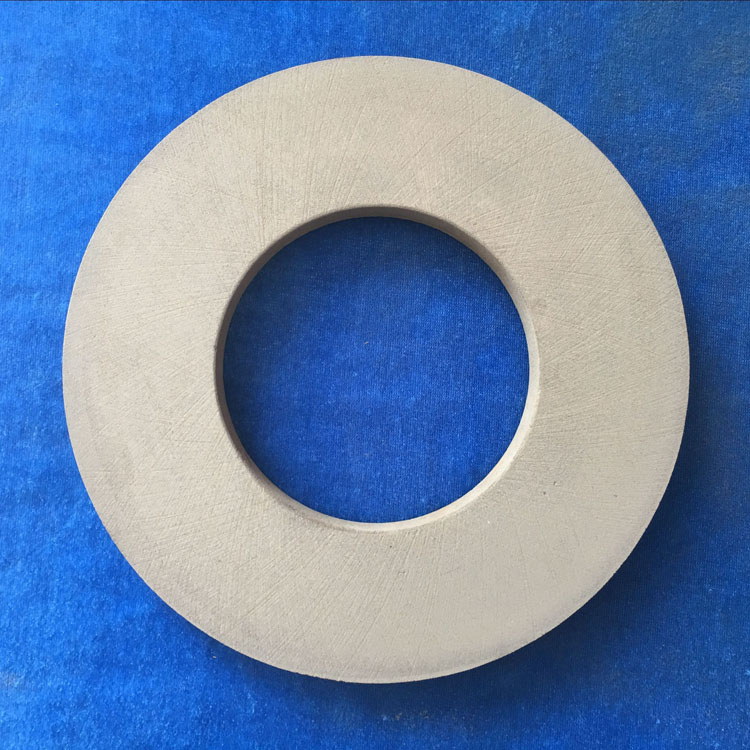

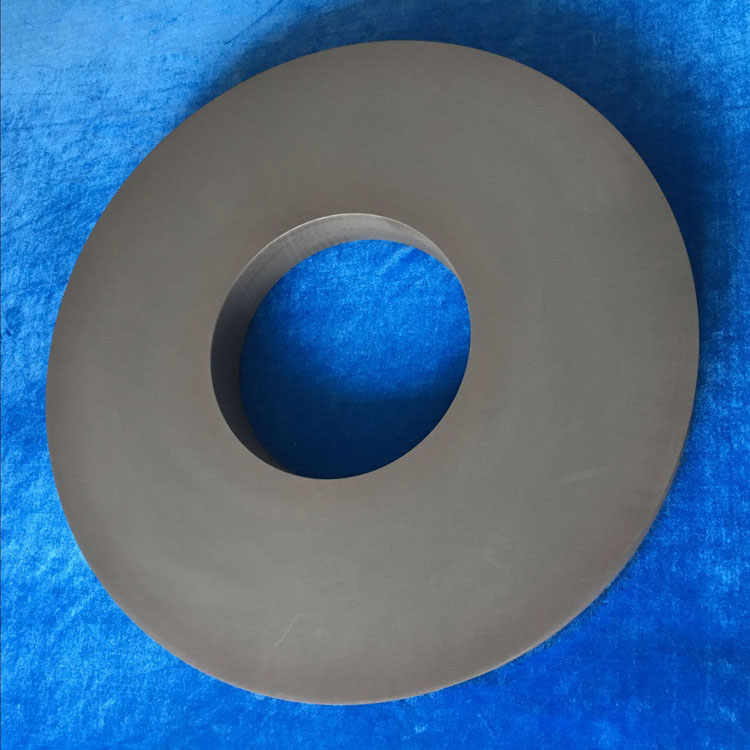

Product detail pictures:

Related Product Guide:

Generally customer-oriented, and it's our ultimate goal for being not only the most trusted, trustable and honest provider, but also the partner for our customers for 2020 Latest Design grinding wheel- Small round grinding wheel with handle grinding head – Kemei , The product will supply to all over the world, such as: Birmingham , Las Vegas , Southampton , Our products are widely recognized and trusted by users and can meet continuously changing economic and social needs. We welcome new and old customers from all walks of life to contact us for future business relationships and mutual success!

The sales person is professional and responsible, warm and polite, we had a pleasant conversation and no language barriers on communication.